Cuplock System Finland for Professional Window Access

Modern buildings across Finland often feature expansive glass façades, narrow ledges, recessed windows, and varying elevations that challenge conventional access methods. While aesthetic design has advanced rapidly, the practical task of reaching and maintaining windows remains demanding. Within this setting, the cuplock system Finland has become a preferred structural approach for window access and cleaning, offering stability, flexibility, and controlled load distribution without relying on permanent installations.

Architecture, Glass, and Access Challenges

Window cleaning and façade maintenance are no longer limited to simple vertical surfaces. Office complexes, residential towers, hospitals, and transport hubs often combine angled glazing, deep frames, and irregular spacing. These design elements complicate access, especially where suspended platforms or mobile towers cannot reach safely.

A system that adapts to these architectural realities must do more than provide height. It must allow precise positioning, consistent alignment, and the ability to work close to the glass without compromising worker balance. Cuplock scaffolding responds to these demands through its modular layout and rigid node connections.

Why Window Access Requires a Different Approach?

Window access is not the same as general construction scaffolding. Cleaning and inspection work involves repeated lateral movement, frequent stops, and careful handling of tools and cleaning equipment. Workers need uninterrupted platform space, predictable footing, and reliable edge protection.

Cuplock systems offer continuous working levels that can be adjusted to window heights with accuracy. This reduces the need for awkward reaching or repositioning that often leads to fatigue or safety concerns. For long façades, the system supports uninterrupted horizontal runs, allowing teams to move steadily rather than constantly dismantling and reassembling access equipment.

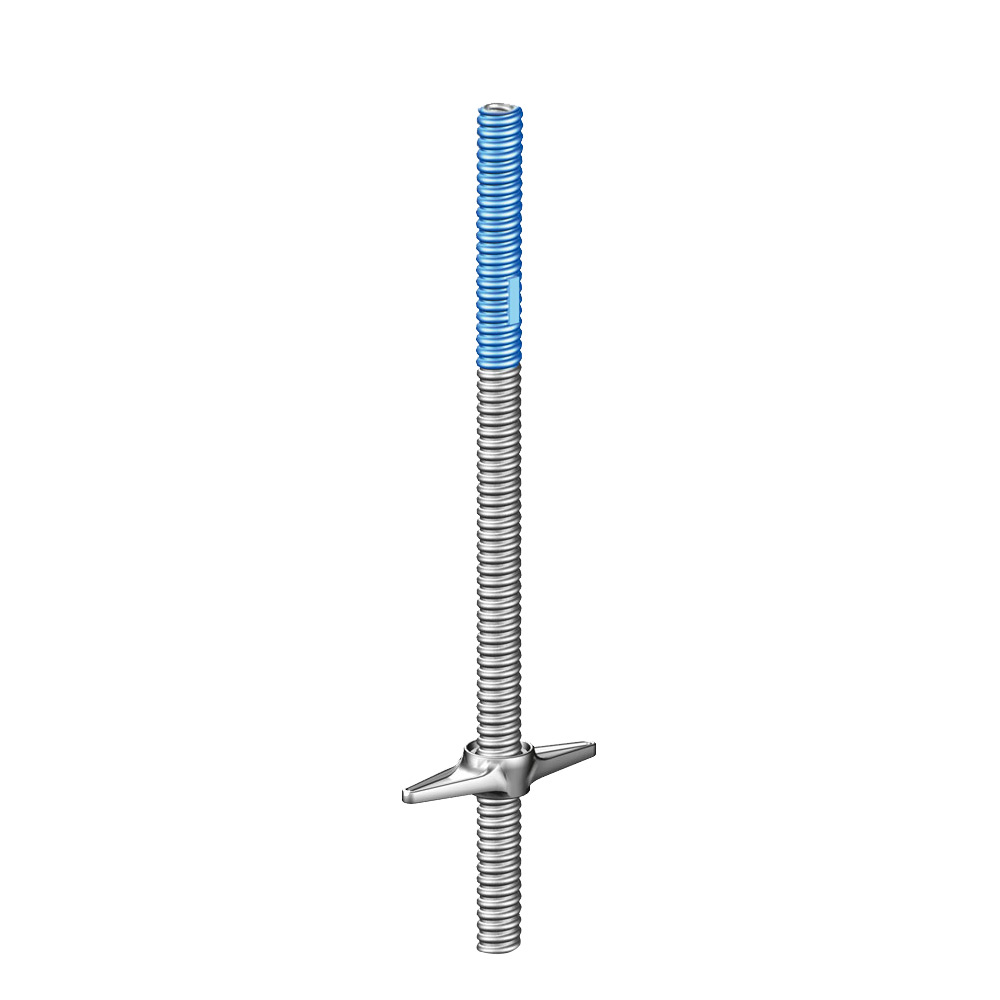

Structural Logic Behind the Cuplock Design

The defining feature of cuplock scaffolding lies in its node-based locking mechanism. Vertical standards include fixed lower cups and sliding upper cups, allowing ledgers and transoms to be secured with a single rotational action. This creates a rigid connection that distributes loads evenly across the structure.

For window access and cleaning, this rigidity matters. Platforms remain stable even when workers shift weight or handle water-fed poles and equipment. The system resists sway, which is particularly important when working close to glass surfaces where sudden movement can cause damage or accidents.

Adaptability to Finnish Building Conditions

Finland’s built environment presents a mix of older masonry structures and modern glass-heavy designs. Seasonal conditions add another layer of complexity, with cold temperatures, wind exposure, and moisture affecting access planning.

Cuplock scaffolding adapts well to these conditions due to:

- High load-bearing capacity suitable for protective sheeting

- Compatibility with weather screens and debris netting

- Stable base arrangements for uneven or frozen ground

- Secure connections that remain reliable under vibration

These qualities support consistent window access even during extended maintenance schedules.

Precision Placement Along Façades

Window cleaning requires platforms to align precisely with sill heights and mullions. Cuplock systems allow vertical spacing to be adjusted in regular intervals, giving planners control over platform positioning. This precision reduces the need for makeshift solutions that compromise safety.

On buildings with stepped façades or varying window sizes, the system can be adapted bay by bay. Transoms and ledgers can be repositioned without altering the entire structure, supporting efficient progression along the building envelope.

Worker Safety and Confidence at Height

Safety is not only about compliance; it directly affects work quality. When cleaners feel secure, they focus on thorough results rather than maintaining balance. Cuplock platforms support full guardrail systems, toe boards, and internal ladder access, creating a contained working zone.

Stable handholds and consistent platform widths reduce the risk of slips, especially when surfaces become wet during cleaning operations. This stability encourages proper technique and reduces rushed movements that lead to errors.

Workflow Efficiency for Repetitive Tasks

Window cleaning often follows a repetitive pattern: approach, clean, inspect, move laterally, repeat. Cuplock scaffolding supports this rhythm by minimizing interruptions. Long platform runs reduce the need for constant repositioning, allowing teams to maintain momentum.

For large buildings, this efficiency can significantly shorten project duration. Reduced setup changes mean fewer disruptions to occupants and smoother coordination with facility management.

Comparison With Alternative Access Methods

While rope access and suspended cradles serve specific purposes, they are not always suitable for extended or detailed window work. Rope systems require specialized training and are sensitive to wind conditions. Suspended platforms depend heavily on roof anchorage and may limit lateral movement.

Cuplock scaffolding provides a grounded alternative that supports sustained work periods and accommodates multiple workers simultaneously. It also allows tools, water systems, and protective materials to be stored directly on the platform, reducing reliance on hoisting.

Load Management and Equipment Handling

Window cleaning equipment has evolved beyond basic squeegees. Water-fed poles, filtration units, hoses, and protective barriers all add weight and complexity. Cuplock systems handle these loads effectively through evenly spaced standards and robust ledger connections.

This load management capability allows crews to work without constantly clearing platforms, improving both safety and productivity. Equipment remains within reach, reducing unnecessary movement.

Integration With Cleaning Technologies

Modern cleaning techniques often involve purified water systems and extended-reach tools. Cuplock scaffolding integrates well with these technologies, providing anchor points for hose management and stable surfaces for filtration units.

The ability to secure equipment directly to the structure prevents entanglement and trip hazards. This integration supports cleaner workflows and reduces strain on workers.

Planning and Assembly Considerations

Efficient use of cuplock scaffolding depends on thoughtful planning. Site surveys assess ground conditions, façade geometry, and access constraints. Once planned, assembly follows a predictable sequence that minimizes errors.

Key planning benefits include:

- Clear load paths for equipment and personnel

- Consistent platform heights aligned with window rows

- Defined access points for safe entry and exit

- Space allocation for pedestrian and vehicle movement

This structured approach supports safer operations from start to finish.

Reduced Downtime for Building Occupants

Window cleaning often takes place on occupied buildings. Noise, visual obstruction, and restricted access can disrupt daily activities. Cuplock scaffolding helps reduce these impacts by enabling faster completion and cleaner site organization.

Because the system remains stable once erected, work progresses steadily without repeated dismantling. This predictability benefits both contractors and building users.

Maintenance and Reuse Over Multiple Projects

Cuplock scaffolding is designed for repeated use across different sites. Components withstand frequent assembly cycles without losing structural integrity. This durability makes the system suitable for contractors handling regular window cleaning contracts.

Standardized parts simplify inspection and replacement. Damaged components can be isolated without affecting the rest of the structure, supporting long-term reliability.

Environmental and Practical Considerations

Sustainable building maintenance increasingly values reusable systems that reduce waste. Cuplock scaffolding aligns with this mindset by offering long service life and adaptability. Instead of relying on disposable or single-use access solutions, contractors can reuse the same system across multiple projects.

Efficient material use also reduces transport frequency, contributing to lower operational impact over time.

Training and Crew Familiarity

Many access professionals are already familiar with cuplock assembly principles. This familiarity shortens training time and supports consistent safety practices. Clear node connections reduce the risk of incorrect assembly, which is critical when working near fragile glass surfaces.

Experienced crews can assemble structures quickly while maintaining accuracy, balancing speed with care.

Supporting Inspection and Maintenance Beyond Cleaning

While window cleaning is a primary application, cuplock scaffolding also supports inspection, seal replacement, and minor façade repairs. This multi-purpose capability adds value for facility managers seeking a single access solution for varied tasks.

By accommodating different maintenance needs, the system reduces the need for multiple access arrangements throughout the building lifecycle.

Key Advantages for Window Access and Cleaning

- Stable platforms aligned precisely with window levels

- Continuous horizontal access along façades

- High load capacity for modern cleaning equipment

- Reliable performance under challenging weather conditions

- Adaptability to complex architectural designs

Each advantage contributes to safer and more controlled operations.

Coordination With Safety Regulations

Finnish safety standards place strong emphasis on fall protection and structural stability. Cuplock scaffolding supports compliance through integrated guardrails, defined access routes, and predictable load behavior.

Clear documentation and standardized components simplify inspection and approval processes, reducing administrative friction for contractors.

Long-Term Value for Service Providers

For cleaning companies and maintenance contractors, investment decisions revolve around reliability and versatility. Cuplock systems deliver value by supporting a wide range of building types without frequent modification.

This flexibility strengthens service offerings and allows providers to take on more complex projects with confidence.

Conclusion

Window access and cleaning demand more than height; they require stability, precision, and adaptability. Cuplock scaffolding meets these demands through its structural logic and practical design. By supporting safe movement, efficient workflows, and reliable load management, it aligns closely with the realities of modern Finnish architecture.

For professionals tasked with maintaining glass-heavy buildings, this system offers a dependable foundation that balances safety, efficiency, and long-term practicality.```

코드를 입력하세요