Automation in Cell Therapy: The Future of Efficient Processing Systems

The field of cell therapy has evolved significantly over the past decade, largely driven by advancements in technology and a deeper understanding of regenerative medicine. As the demand for more personalized and effective therapies grows, so does the need for enhanced production methods that can handle complex processes with precision. Enter automated cell therapy processing systems—revolutionizing how we manufacture and scale up these life-saving treatments.

Automating cell therapy processes isn’t just a trend; it’s a necessary evolution in the industry. These systems are streamlining complex procedures, reducing human error, improving scalability, and enabling more efficient and cost-effective production of cell-based therapies. Let's dive deeper into how automation is shaping the future of cell therapy and why it’s considered a game-changer in the medical and pharmaceutical fields.

What Is Automated Cell Therapy Processing?

Automated cell therapy processing refers to the use of automated systems and technologies to carry out tasks that were traditionally performed manually in the manufacturing process of cell-based therapies. This includes everything from harvesting, culturing, and expanding cells to preparing and delivering final therapeutic products. By leveraging robotics, artificial intelligence (AI), and sophisticated software, these systems aim to make the process faster, more reliable, and scalable.

Cell therapy involves manipulating living cells to treat or cure diseases. Some of the most common examples include CAR-T (Chimeric Antigen Receptor T-cell) therapies, stem cell treatments, and other forms of regenerative medicine. These therapies have shown immense promise in treating cancers, genetic disorders, and chronic conditions. However, scaling up production while maintaining high-quality standards has always been a challenge—until now.

The Benefits of Automation in Cell Therapy

1. Improved Consistency and Precision

One of the biggest challenges in cell therapy production is maintaining consistent quality. Manual handling of cells can lead to variations in process results due to human error, inconsistencies in technique, or environmental factors. Automated systems, however, can provide controlled environments and repeatable processes that ensure cells are treated consistently every time.

For instance, automated systems can control factors like temperature, pH, and oxygen levels in cell cultures, which are crucial to cell growth and viability. These automated controls help reduce the risk of contamination or degradation, leading to more reliable and high-quality therapies.

- Increased Efficiency and Reduced Time

Automated processing systems are significantly faster than manual processes. Tasks like cell washing, culturing, and separation that once took hours or days can now be completed in a fraction of the time. This efficiency is vital when dealing with therapies that rely on fresh cells, such as CAR-T, where time is of the essence in ensuring the highest quality product.

By automating key processes, manufacturers can process more batches in a shorter time frame, which is crucial for meeting increasing global demand for cell-based therapies. This faster processing time also ensures that treatments are delivered to patients more quickly, improving patient outcomes.

- Cost Reduction

In the world of healthcare, cost-effectiveness is a priority. While implementing automation systems initially requires a significant investment, they ultimately lower costs by reducing the need for labor, minimizing human errors, and ensuring optimized processes. For example, the need for trained specialists to handle delicate manual procedures is minimized, allowing resources to be allocated more efficiently.

Moreover, automated systems enhance productivity by increasing throughput and reducing the likelihood of costly mistakes. This reduction in errors and improved consistency translates into lower production costs, which can help make advanced cell therapies more affordable and accessible to patients.

- Scalability

Scalability is another major advantage of automation in cell therapy. As the demand for cell-based therapies grows, manual processes simply cannot keep up. Automation allows companies to scale up their production capabilities to meet demand without compromising the quality of the product.

For instance, automated systems can easily scale to process hundreds or even thousands of samples without requiring extensive changes to existing infrastructure. This ability to scale efficiently is crucial as more cell-based therapies enter the market and the need for high-quality, mass-produced treatments increases.

- Streamlined Regulatory Compliance

The healthcare and pharmaceutical industries are heavily regulated, with strict guidelines around product quality, manufacturing practices, and safety. Automated systems are designed with built-in documentation and tracking capabilities that help ensure regulatory compliance. These systems can automatically log data, create batch records, and provide traceability, making it easier for manufacturers to meet the regulatory requirements of agencies like the FDA.

Furthermore, automated systems can incorporate real-time quality control and process monitoring, which helps maintain compliance with good manufacturing practices (GMP). This ensures that the product meets the highest standards and reduces the risk of non-compliance, saving companies time and money during audits.

The Role of Artificial Intelligence in Automation

Artificial intelligence is playing a pivotal role in revolutionizing automated cell therapy processing. AI technologies are being integrated into these systems to provide deeper insights into process optimization. Machine learning algorithms can analyze large datasets from production runs to identify patterns, detect anomalies, and predict outcomes. This allows for the continuous improvement of the manufacturing process.

AI-driven systems can also provide personalized feedback on cell therapy production. For example, AI can monitor the health of individual cell cultures and adjust parameters in real-time to optimize cell growth and productivity. These advancements will help make cell therapy processing even more precise and tailored to the unique needs of each patient.

Challenges and Future Outlook

While automation in cell therapy processing has tremendous potential, it’s not without its challenges. High upfront costs for automation equipment and technology integration can be a barrier for smaller companies or startups. Additionally, the technology is still evolving, and there may be unforeseen obstacles in achieving full automation across all types of cell therapies.

However, the future looks promising. As the technology matures and costs decrease, automated systems will likely become more accessible to a broader range of manufacturers. Furthermore, advancements in AI, robotics, and cloud computing will continue to enhance the efficiency and flexibility of automated systems, further driving innovation in the cell therapy space.

Conclusion

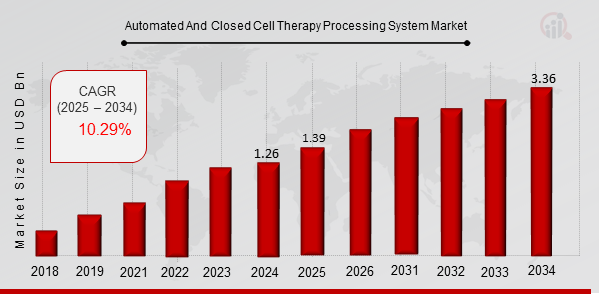

The automated cell therapy processing system market is primed for significant growth as automation technology continues to mature. By improving consistency, efficiency, and scalability, these systems are not only optimizing the production process but also making life-saving therapies more accessible and affordable. With advancements in AI and machine learning, automation will continue to push the boundaries of what’s possible in cell-based therapies. As we move further into 2025, automated systems will undoubtedly play a central role in shaping the future of regenerative medicine and personalized healthcare.