EPDM Foam Supplier for Industrial & Commercial Applications

Choosing the right EPDM Foam Supplier is critical for industries that require durability, weather resistance, and long-term performance. EPDM foam is widely used across automotive, HVAC, construction, marine, and electrical sectors due to its excellent resistance to UV rays, ozone, moisture, and temperature variations. A reliable supplier ensures consistent quality, precise specifications, and dependable delivery for every project.

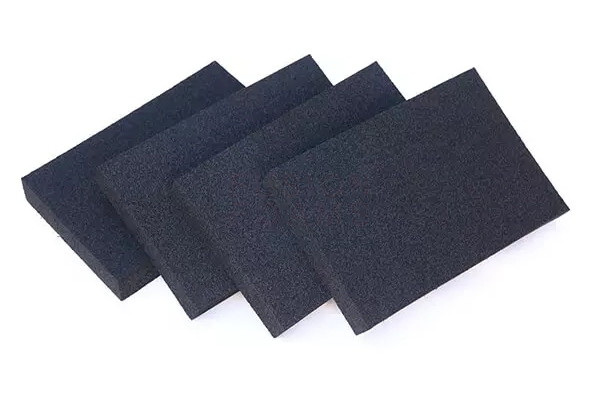

As a professional EPDM Foam Sheet Supplier, manufacturers focus on delivering sheets that offer superior sealing, insulation, and vibration-dampening properties. EPDM foam sheets are commonly used in gaskets, wall padding, acoustic insulation, and protective linings. These sheets are lightweight, flexible, and easy to fabricate, making them ideal for both indoor and outdoor applications.

High-Quality EPDM Foam Sheet Supplier

An experienced EPDM Foam Sheet Supplier provides products in various thicknesses, densities, and custom dimensions to meet industry-specific needs. EPDM foam sheets are closed-cell in structure, ensuring minimal water absorption and excellent thermal insulation. This makes them suitable for roofing systems, electrical enclosures, and industrial sealing solutions.

Suppliers who follow strict quality control processes ensure uniform cell structure, smooth surface finish, and consistent performance. Whether used for shock absorption or thermal insulation, EPDM foam sheets maintain elasticity over time, even in harsh environmental conditions.

Reliable EPDM Foam Roll Supplier

Working with a dependable EPDM Foam Roll Supplier allows businesses to source continuous foam material for large-scale applications. EPDM foam rolls are commonly used in expansion joints, duct insulation, sealing strips, and flooring underlays. Rolls provide ease of installation and reduced material wastage, especially for long-length sealing requirements.

A professional EPDM foam roll supplier ensures accurate roll widths, controlled density, and excellent compression recovery. These qualities make EPDM foam rolls ideal for industries that demand flexibility and long-term sealing performance.

EPDM Foam Manufacturer and Supplier with Custom Solutions

A trusted EPDM Foam Manufacturer and Supplier offers end-to-end solutions, from raw material selection to final product delivery. Manufacturing expertise ensures the foam meets international standards while maintaining resistance to chemicals, heat, and aging. Advanced production techniques help achieve consistent quality across sheets and rolls.

Customization is a key advantage when working directly with an EPDM foam manufacturer. Custom densities, die-cut components, adhesive-backed foam, and application-specific formulations allow industries to meet exact technical requirements. This approach improves product efficiency and reduces installation time.

Why Choose a Professional EPDM Foam Supplier?

Partnering with an established EPDM foam supplier ensures long-term reliability, cost efficiency, and product consistency. High-grade EPDM foam enhances sealing efficiency, reduces energy loss, and extends product lifespan. Suppliers who focus on innovation and quality help industries achieve better performance outcomes.

At Fusion Foams, the focus remains on precision manufacturing, consistent material quality, and application-driven solutions that meet diverse industrial requirements.

Frequently Asked Questions (FAQ)

Q1. What are the main advantages of EPDM foam?

EPDM foam offers excellent resistance to UV, ozone, heat, moisture, and aging, making it ideal for outdoor and industrial applications.

Q2. What is the difference between EPDM foam sheets and rolls?

Sheets are used for fixed-size applications like gaskets and insulation panels, while rolls are suitable for continuous sealing and large-area coverage.

Q3. Can EPDM foam be customized?

Yes, a professional EPDM foam manufacturer and supplier can provide custom thickness, density, sizes, and adhesive backing.

Q4. Which industries use EPDM foam products?

EPDM foam is widely used in automotive, construction, HVAC, electrical, marine, and industrial sealing applications.

Q5. How do I choose the right EPDM foam supplier?

Look for quality certifications, customization capabilities, consistent supply, and proven industry experience. Get Direction