1. Introduction

1) Major Issues in PAC

- Planning and release of individual orders to shop floor and vendors

매장 및 공급 업체에 대한 개별 주문 계획 및 출시 - Detailed scheduling and control of jobs : dispatching or sequencing

상세 예약 및 작업 제어 (파견 혹은 순서 지정) - Feedback on shop and supplier's performance against plans

계획에 대한 상점 및 공급 업체 성과의 피드백 - SOP(Product family) → MPS(End Item) → MRP(Part) → Many Open orders

- Dept 팀 → Work center → Work stations

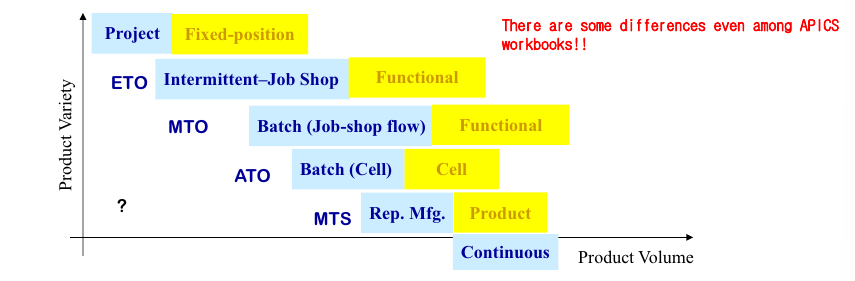

2) Manufacturing Env ↔ Process types ↔ Layout

| Category | Batch Process | Flow Processes | ||

| Process type | Jobshop or Interm | Batch flow | Repetitive | Mass/continuous |

| Layout | Functional | Product | ||

| Routing | Product specific | Fixed | ||

| Scheduling | Op scheduling | Op or rate scheduling | Rate-based scheduling | |

| Control | MRP/PAC | MRP, process flow sch | ||

| Transaction req't | Very high | Medium | Low | |

| Productivity tools | Lean, TOC, 6-SIGMA |

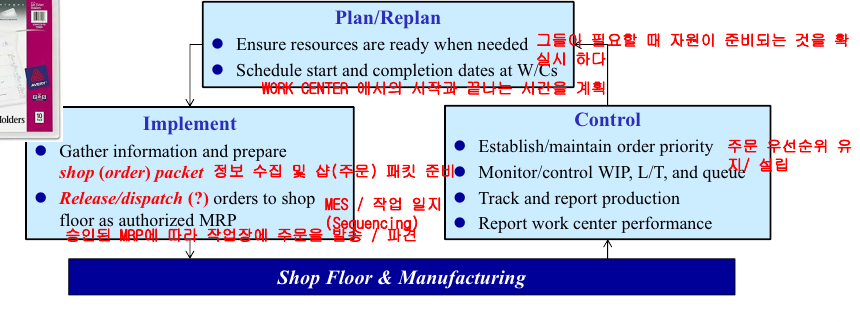

(2) PAC functions and ffeedback

Information requirements 필요로 하는 정보

: shop order no(order quantity, duedates), qt'y on hand

shop order number(주문량, 납기일, job order, open roder, job ticket → W/O), 재고량

- Op's required, assigned work centers & capacity, mfg LT, op times, on-order qt'y

필요로 하는 생산, work center 와 용량의 배치, 생산 리드 타임, 생산 시간, 주문에 있는 수량(P/O) - BOM, efficiency/ utilization, tools required, qty available

(3) Overview of Control in PAC

a) Goals 목표

meet delivery dates, best use of resource 납기 일을 충족, 자원의 최적 의 사용

→ dispatching rule 우선순위 규칙 ↔ dispatch list 우선순위 리스트

- Objectives 목적 : control progress of orders, L/T, queue,...

- Control levers : order priorities, I/O of work, flow rate

b) Types of processes

- Batch Process

- Prioritize / sequence / authorize W/Os, report to production control

- Flow process

- use visual system to authorzie production start, and maintain a planned prod rate

- Work order 가 딱히 없다

c) Types of PAC

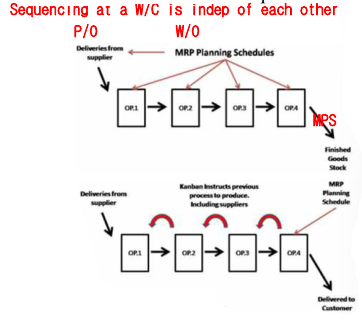

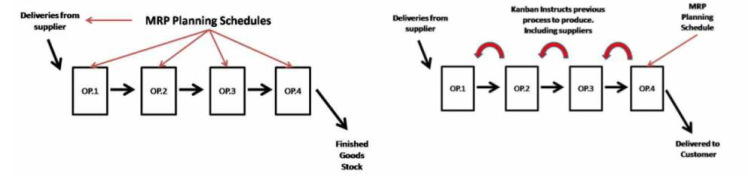

- Push (MRP ; by w/o) vs. pull(JIT or Lean ; by Kanban)

(4) Push or MRP Systems

a) Push for batch process

- Create time-phased schedules 시계열 계획을 만든다

- Release and push W/Os through operations based schedule

운영 기반 일정에서 W/O 해제 및 푸시 - Use MRP-based PAC and Maximize capacity utilization

MRP 기반 PAC를 사용하며 용량 사용량을 최대화한다.

b) Push for flow process

- Create rate-based schedules 비율 기반 계획을 만든다 → no W/O

- Maximize rate of product flow, and produce FGI planned

제품 흐름 비율 극대화 및 계획된 FGI 생산 - Uninterrupted runs, fixed routing, committed lines

- tools : tackt time, control of WIP levels,...

- Sequencing at a W/C depends on the next 작업장의 순서는 다음 순서에 종속된다

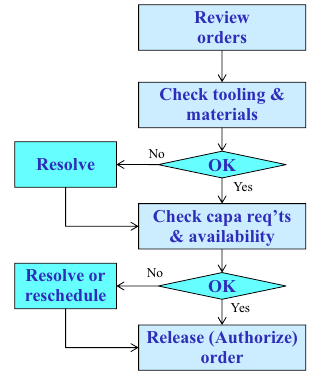

(5) Order Release : Authorizing Production

a) Authorization process

- Review orders

- MRP planned orders, current priority MRP

MRP 계획 주문, 현재 우선 순위 MRP - Consider production schedule, rate and duration of production run

생산 계획, 비율, 그리고 생산 수행의 기간을 고려한다.

- MRP planned orders, current priority MRP

- Check tooling and materials

- Tooling : not considered in MRP, and so to be checked

Tooling : MRP에서는 고려되지 않으므로 점검해야 한다 - Materials : check with MRP exception reports

자재들 : MRP 예외 보고서를 확인

- Tooling : not considered in MRP, and so to be checked

- OK

- Alternatives 대안들 : Expediting, subsituting, queue, partial building

- Check capa req'ts and availability

- If CRP is not used, check available capa

만일 CRP가 사용되지 않았다면 가용 용량을 확인

- If CRP is not used, check available capa

- OK

- Alternatives : increasing capa or adjusting load

- Release (Authorize) order

- Generate a shop(order) packet

- Shop order(packet) to the manufacturing department

b) Shop order packet

- Order no and part no, name and descriptions, quantity

- Engineering drawings, BOMs, route sheets, tool requisitions authorizations

- Tickets

- job tickets for each operation, move tickets between operations, material issue ticket with picking list (불출 / 인출 전표)

2. A framework for PAC

PAC begins when an order is released 주문이 승인되면 PAC가 시작된다.

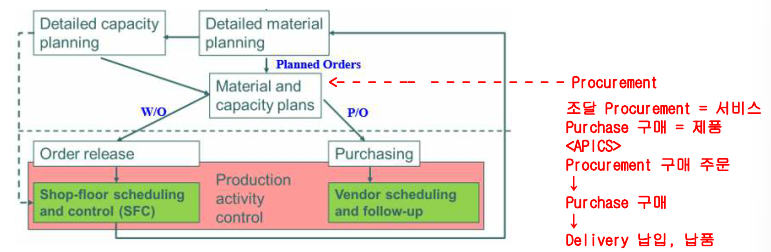

1) MPC System Linkages and Linkages between MRP and PAC

MPC 시스템 연결과 MRP와 PAC 사이의 연결

MRP Environment : job-shop, long leadtimes, high WIP, highly saturated work centers

MRP 환경 : Job-shop, 긴 리드타임, 높은 공정 중 재고, 포화도가 높은 작업장

(1) To Detailed Capacity Planning

- Planning information to PAC PAC에 대한 계획 정보

- critical to managing the detailed shop-floor flow of material

자재의 상세한 작업장 흐름을 관리하는데 매우 중요함

- critical to managing the detailed shop-floor flow of material

- Feedback from PAC status and warning PAC 상태 및 경고로부터의 PAC

(2) To Detailed Material Planning

- Planning information to PAC PAC에 대한 계획 정보

- Provide the right part at the right time 적절한 부품을 적시에 제공

- Feedback from PAC status and warning PAC 상태 및 경고로부터의 PAC

2) JIT Effect on PAC

Job-shop(batch) environment:

product-specific routing, long L/T, high WIP, high utilization

-

JIT environment

- cell manufacturing, short lead times, low WIP, fexible capacity

셀 형식의 생산, 짧은 리드타팀, 낮은 공정 중 재고량, 유연한 용량 - Utilization is not a issue 가동율은 중요 요인이 아니다

; JIT에서는 Throughput, LT, Inventory 가 중요

- cell manufacturing, short lead times, low WIP, fexible capacity

-

Formal systems for SFC are largely unncessary under JIT

SFC에서의 기존 시스템은 JIT 시스템 상에서 크게 상관 없다

→ Simplify PAC functions PAC 기능을 단순화-

Order release through kanbans or other pull system

칸반 혹은 다른 pull 시스템에서의 주문 release

→ limited WIP inventories 제한된 WIP 재고 -

Detailed scheduling is not needed 상세한 게획은 필요 없다

→ Fixed sequence (Heijunka 평준화) 고정된 순서

-

No data collection or monitoring requirements 데이터 수집과 요구사항의 감독이 없다

→ Back flushing: monitoring only raw material and FGI 원재료와 FGI만 관리

-

-

Vendor scheduling may be more complex under JIT

JIT 환경 하에서 공급자 스케줄링은 훨씬 더 복잡하다- Delivered in the exact sequence as the build schedule

제조 일정대로 정확한 순서대로 배송

↔ No shipping / receiving document 배송/입고 서류 없음

- Delivered in the exact sequence as the build schedule

3) The company environment

PAC objectives reflect the firm's strategy and competitive position

PAC의 목적은 회사의 전략과 경쟁 위치를 반영한다.

(1)PAC Objective

- Primary Objective

- Managing material flows to meet MPC plans MPC 계획을 만족하기 위해 자재의 흐름을 관리한다.

- Other objectives

- efficient use of capacity, labor, tools, time, or material

용량, 노동력, 기기, 시간, 자재의 효율적 사용

- efficient use of capacity, labor, tools, time, or material

- Objectives under JIT

- material velocity 자재 속도 (L = λW & Quality)

3. PAC Techniques

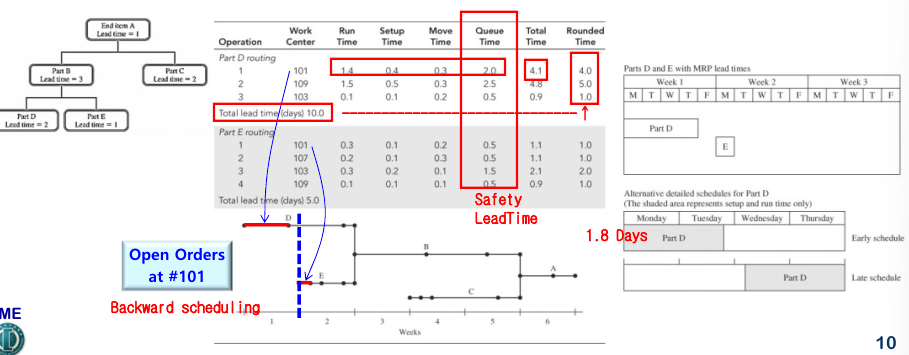

1) Overview of PAC Scheduling

(1) Elements of scheduling

- Operations required, sequence and routing of op's, work centers for each op's

요구되는 운영, 운영의 순서와 경로, 각각의 운영에 따른 작업장 - Start and finish dates of each op, time estimates for each op

각각의 운영의 시작되는, 그리고 종결되는 날, 각각의 운영에 걸리는 시간 예측

(2) Inputs to shceduling

Due date, machine maintenance, expected rework and scrap

- Preventive maintenance 예방 정비 (PM)

- adjustments, replacements, basic cleanliness

- Predictive maintenance 예측 보전

- based on statistical analysis 통계 분석을 기반으로

- E.G : MTBF = Mean Time Between Failures

(3) Scheduling Techniques

Operation setback and Gantt charts, priority control and sequencing, TOC

- Priority based on current shop floor conditions, changeover costs, material availability

현재 shop floor 상태에 기반으로 한 우선순위, 변경비용, 자재 가용성 - Sequencing determines the order of jobs at work centers : guided by priority rules

순서는 작업장에 있는 작업의 순서에 따라서 결정된다 : 우선순위 규칙에 의해서

(4) Scheduling for MRP

- Forward or backward scheduling, infinite vs finite loading

- Other issues : time fence policies (MPS), FAS(ATO)

2) Basic SFC Concepts

Routing and lead-time data are essential inputs 경로와 리드타임 데이터는 투입에 필수적이다

- Routing 경로

- to specify the operation, its duration, and the work center performing the work

운영과 그의 기간, 그리고 그 작업을 수행하는 작업장을 구분하기 위해

- to specify the operation, its duration, and the work center performing the work

- Lead times

- Queue time → setup time → runtime(=machine run time * lot size) → move time

- Good SFC practice can reduce each component

좋은 SFC 정책은 각각의 요소를 줄일 수 있다

3) Lead-Time Management

(1) Basic principle of MPC system

- Substitute information for inventory

재고를 만들지 말아라 ; 재고에 대한 정보를 대체한다 - The knowledge of when an order will arrive at a work center replaces the need to WIP inventory feeding the work center

주문이 언제 작업장에 도착할 것인가에 대한 정보는 작업장에 있는 공정 중 재고의 필요성을 대체한다.

(2) Typical method for calculating lead times

- Manufacturing

- queeu → setup → run → wail → move → queue → setup...

- operation time(processing time) = setup + run

- interoperation time = wait + move + queue

- little's law

- L = λW

- L = Average number of items in a system 시스템 내에서 상품의 평균적인 개수

- λ = Average arrival rate 평균적인 도착률

- W = Average wait time in the system for an item 상품의 평균적인 대기 시간

- Find non-queue time : setup + run + move

- Convert the time unit to days 시간 단위를 일들로 바꾼다

- number of shifts, 7 productive (or available) hours per shift

- Set queue time : queue time should be continuously monitored

- 2 days ; if the next work center is in another department

- 1 day ; if in a different work center in the same department

- 0 day ; if on the same machine

- Lead time = rounded sum ( in weeks) of queue + non-queue times

4) Gantt Chart

- Gantt charts (or bar charts) show a schedule

- Each step listed separately

- Relationship between steps portrayed visually

- Updating : actual data must be captured and integrated into ongoing replanning cycle

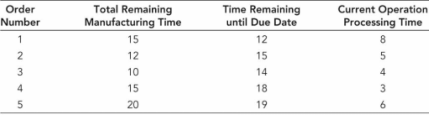

5) Priority Sequencing Reules

Determine which job to run next at a particular work center

특정 작업장에서 어떠한 작업을 다음으로 실행할 것인가를 결정한다.

(1) Common Rules

- FCFS (First Come First Service), EDD (job due date or opereation due date; 납기일이 가까운 것부터)

- Least slack (order slack or slack time)

- work on the job with the least total slack

여유 시간이 적은 쪽부터 - Total slack time = due date - sum(operation times of all remaining operation)

- operation times = setup + run time

- work on the job with the least total slack

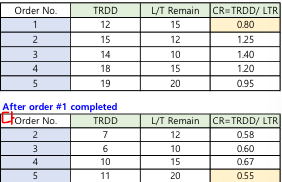

- Slack time per operation

= min{total slack time / # of remaining operations} - Critical Ratio

- Min {time remaining / LT remaining }

- CR <1 ; behind schedule

- CR = 1 ; On time

- CR > 1 ; Ahead of schedule

- Time remaining = due date - present time

- L/T (or work remaining) = setup + run + move + queue

- Min {time remaining / LT remaining }

- SPT = Shortest operation next rule

- min{setup + run}

- Maximize the number of jobs processed and minimize the number of W/Os waiting in queue

처리되는 작업의 술를 최대화 하고 대기열에서 대기하는 W/O의 수를 최소화한다.

- Least work remaining

- min{operation(=setup + run) times of all remaining operations}

- Fewest operation remaining : min {# of remaining operations}

(2) Dispatch list generated by MES and/or local APS

- Develop operation start/due dates for determining priority sequence decisions

우선순위 결정을 위한 작업 시작/기한 작성

(3) Example

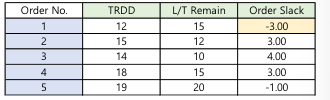

- Critical Ratio = min{time remaining / LT remaining}

- Time remaining = due date - present time

- L/t (or work) remaining = setup+run+move+queue = Manufacturing time

- EDD = job due date or operation due date

answer : 1-3-2-4-5 순 - Shortest operation next (SPT rule) : min {setup + run} = Current Operation Processing Time의 최소

answer : 4-3-2-5-1 - Least slack (order slack or slack time)

- Total slack time = due date - ∑ remaining operation (=setup + run) times

- Total slack time = due date - ∑ remaining operation (=setup + run) times

6) Theory of Constraints(TOC)

OPT (Optimized Production Technique)

one of the first-generation APS

(1) Basic principles : Holistic philosophy ↔ Systems THinking

- Throughput-based thinking ; 산출량 = 완제품 생산율 * 시간

- Throughput : the rate at which system generates money through sales

- 산출량 = 팔릴수 있는 상품의 비율 (현금창출량)

- Focusing on the constraint 제약에 집중

- Constraints

- throughput-based(real or physical) ↔ behavior-based(lack of understanding)

- Throughput-based constraints

- Internal(physical resources) vs. External(market constraints)

- Constraints

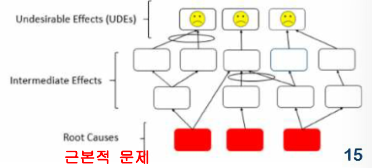

(2) Thinking process of TOC

- What would be changed? 무엇이 변해야 하는가 (문제점 도출)

- What should it be changed to? 어떠한 모습이 바람직한가

- How should a change be created 그러한 모습을 어떻게 만들 것인가

(As-Is Analysis 현황 분석 → To-Be analysis → Gap Analysis 차이 분석)

-

6 logic trees

- GT = Goal Tree, CRT = Current Reality Tree

- EC = Evaporating Clouds, FRT = Future Reality Tree

- PRT = Prerequisite Tree, TT = Transition Tree

(3) General applications

a) VATI analysis

- logical flow of materials from the raw stage to finished products

원재료부터 완제품까지의 물질의 논리적 흐름 - V = 1-to-many ; steel, paper

- A = many-to-1; ass'y

- T = many-to-many ; PC

- I = 1to1; fab

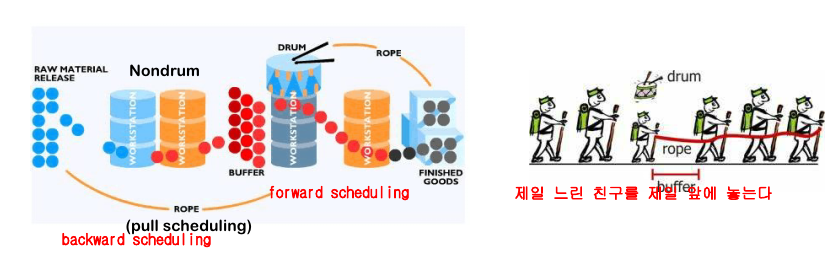

b) Drum-Buffer-Rope planning : 5 Focusing steps

Managing the TOC Schedule

- Identifying the system's constraints : use RCCP

- Exploiting the drums

- If necessary, add capacity to drums by moving work or outsourcing

- Subordinating non-bottlenecks 부수적 비병목 자원

material relase-ropes- Release raw materials to non-bottlenecks only when scheduled

일정이 잡힐 때에만 원재료를 비병목으로 보낸다 - Productive management of buffers

- Ensure that bottleneck resources are not starved for order

병목 자원에서 주문이 부족하지 않도록 보장

→ Buffer coordinator - Red zone (next batch) → Yellow zone → Green zone (batches scheduled furthest)

- Ensure that bottleneck resources are not starved for order

- Release raw materials to non-bottlenecks only when scheduled

- Elevating the drum

- Increase capacity at the bottlenecks to allow the organization to grow

조직을 성장시키기 위해 병목의 용량을 증가시킨다

- Increase capacity at the bottlenecks to allow the organization to grow

- Go back to step 1, and don't stop

; rope 가 없으면 WIP이 증가 → CONWIP(Controlled WIP)

c) Throughput accounting for true performance measures

- Classic cost accounting

- 회계 법칙 상에서는 가동율이 높아져야 원가가 낮아진다

- Inventory(asset) = material costs + direct costs + indirect costs

- 현대 회계에서는 간접비가 가장 중요

- Throughput ↔ Cash flow = Sales revenue 현금창출량

- Throughput cost = sales revenue - true variable costs (직접 변동비 ; 재료, 노무)

- Inventory ↔ ROI = Net profit / investment

- All the money that the system has invested in purchasing things which it intends to sell

시스템이 판매하려는 물건을 구매하기 위해 투자한 모든 돈

- All the money that the system has invested in purchasing things which it intends to sell

- Operational expenses ↔ Net profit = Revenue - (Investment + Expenses)

- All the money the system spends to turn inventory into throughput

재골를 산출량으로 바꾸기 위해 시스템이 사용한 모든 금액

- All the money the system spends to turn inventory into throughput

d) Critical chain method

- TOC applied to project management TOC이론을 프로젝트 관리에 적용한 것

- Individual tasks are not as important as the goals of the project

개별 업무는 프로젝트의 목표 만큼 중요하지는 않는다 - It is important to manage constrainded resource

제약된 자원의 관리가 가장 중요하다

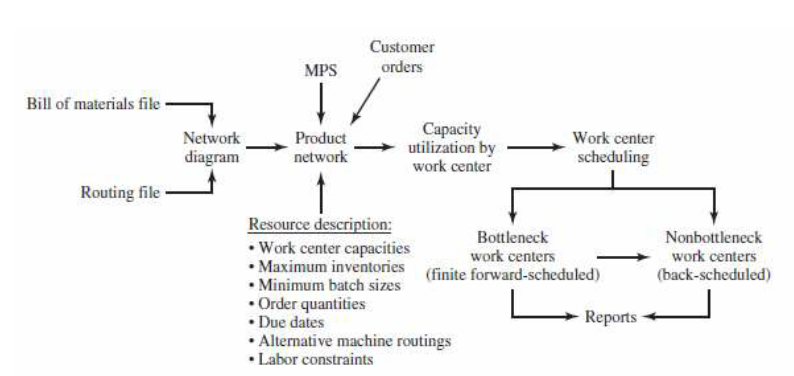

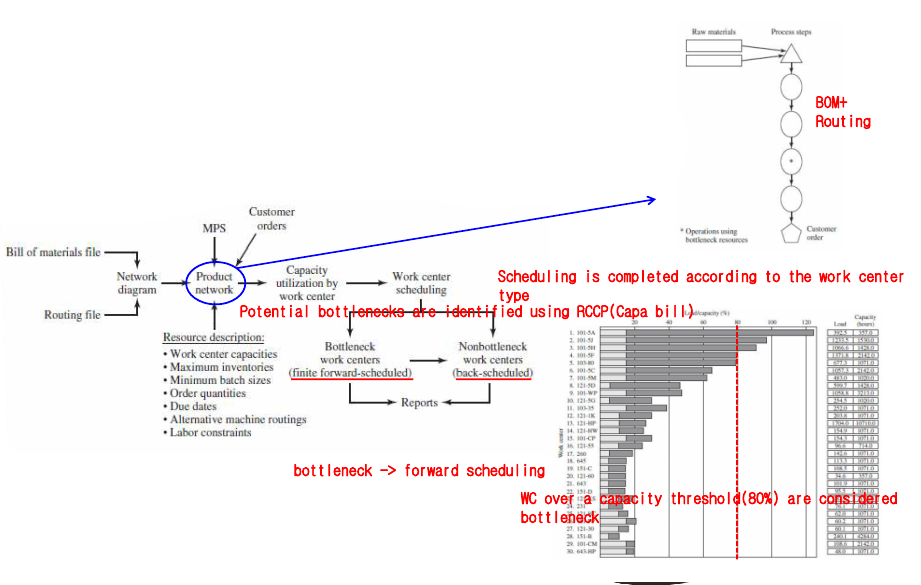

(4) Theory of Constraints System

a) Basic Concepts of TOC Systems

- Bottlenecks limit the capacity of the entire plant

병목이 전체 공장의 용량을 제한한다- Bottleneck = capacity less than the required demand 요구되는 수요보다 작은 용량

→ generalized into "Constraints" - Bottlenecks are of critical concern in scheduling

- Bottleneck = capacity less than the required demand 요구되는 수요보다 작은 용량

- Objective : maximize throughput

목적 : 현금창출을 최대화하는 것- Bottlenecks may be constraints other than work centers

병목자원들은 작업장 보다 더 제약이 된다 - Constraints are identified, buffered with inventory

제약들은 규명되었으며 재고를 완충한다 - Constraints are made clear to the entire factory 제약들은 전체 공장을 깨끗하게 한다

→ Continuous improement (Kaizen 개선)

- Bottlenecks may be constraints other than work centers

b) TOC Scheduling

- Drum Buffer Rope (DBR) Principle

- Bottlenecks are managed for maximum efficiency 병목자원은 최대 효율성을 위해 관리된다

- Material moves through non-bottleneck resources as quickly as possible

가능한 빨리 비병목 자원을 통해 재료를 옮긴다 - Drum

- Bottleneck work centers which control the tempo of workflow through the plant

공장에서 업무 흐름의 속도를 조절하는 병목 작업장 - Drum or bottleneck or CCR (Capacity Constrained Constraint)

- Bottleneck work centers which control the tempo of workflow through the plant

- Buffer

- Inventory to protect the throughput at bottlenecks from random variation

무작위성 변동에서부터 병목 자원의 산출을 보호해주는 재고

- Inventory to protect the throughput at bottlenecks from random variation

- Rope

- use of pull scheduling(JIT; Kanban) at non-bottleneck resource

비병목 자원에서 pull scheduling의 사용

- use of pull scheduling(JIT; Kanban) at non-bottleneck resource

- TOC Scheduling Steps

- Schedule new orders on the bottleneck operations (drums)

병목현상 운영(드럼)에 대한 새 주문 예약- Finite forward scheduling on the drum and succeding operation

드럼에 대한 유한 forward 스케줄링 및 후속 작업 - Finite backward scheduling on numdrums/order

드럼이 아닌 것들의 ㅣ주문에 대한 유한 backward 스케줄링

- Finite forward scheduling on the drum and succeding operation

c) Buffer

- TOC uses both safety stock and safety lead time at bottleneck operations

병목 운영에서 TOC는 Safety stock 과 safety lead time을 동시에 사용한다- Safety stock is held in front of the bottleneck to prevent shortages

Safety stock 은 결핍을 막기 위해 병목 앞에서 보유한다 - Safety lead time is introduced between sequential orders at the bottleneck

병목현상의 순차적 주문 사이에 안전 리드 타임이 도입됨

- Safety stock is held in front of the bottleneck to prevent shortages

d) TOC and Lot Sizing

- TOC uses variable lot sizes to reduce setup times and maximize output at the bottlenecks

TOC에선 setup 시간을 줄이기 위해서, 그리고 병목 프로세스에서의 산출을 최대화 하기 위해 다양한 lot size들을 사용했다.- For the same finished item, lot sizes at different operations may be different

똑같은 완제품에서, 다른 공정에서의 lot size들은 다를 것이다 - In typical finite scheduling, the batch size is fixed or order spllitting is used at bottleneck

특정 finite scheduling에서는 batch size가 고정되고 order splitting을 병목 공정에서 사용한다.

- For the same finished item, lot sizes at different operations may be different

- Lot sizes are calculated differently for bottleneck and non-bottleneck resource

병목 자원과 비병목 자원은 서로 다르게 lot size가 계산된다- TOC splits orders at non-bottleneck resources and combines orders at bottleneck

TOC에서는 비병목 자원에서는 주문을 나누지만 병목 자원에서는 주문을 합친다.- Control procedure must be developed to control split / join batches

분할/결합 배치를 제어하기 위한 제어 절차를 개발해야 합니다.

- Control procedure must be developed to control split / join batches

- Transfer batch (Lot Splitting)

- Batch moving from operation to operation 한 작업에서 다른 작업으로 옮겨지는 batch

- Process batch

- total lot size released to the shop or batch processed by the bottleneck

병목현상으로 처리된 배치 또는 shop에 릴리스된 총 로트 크기

- total lot size released to the shop or batch processed by the bottleneck

- TOC splits orders at non-bottleneck resources and combines orders at bottleneck

- TOC employs lot splitting/overlap or line scheduling

TOC에서는 lot splitting/overlap 혹은 라인 스케줄링을 운용한다- Reduce order flow times 주문 흐름 시간을 줄인다

- Smooth work flow to yiled better use of capacity

용량의 더 나은 사용을 위해 작업 흐름을 평준화 한다.

e) TOC and the MPC Framework

- TOC works in all front-end, engine, and the back-end

→ APS(CS + Math Programming) - TOC might allow less accuracy in non-bottleneck data

비병목 데이터에서는 덜 정확하다

f) TOC Contributions

- 기본적으로 RCCP 기반으로 한다

- Feasible MPS : finite schedule through bottleneck resources

가능한 MPS : 병목 자원을 통한 유한 스케줄 - Shorter LT → Less WIP, greater material velocity

- Eliminate the conflict between MRP and finite scheduling with less computing time

MRP 와 적은 계산 시간을 가진 유한 스케줄링 사이의 충돌을 제거했다

g) Implementation Issues

- Paradigm shift : a major shift in manufacturing mindset

- It is OK to not work (at a non-bottleneck) if there are no order

주문이 들어오지 않는다면 비병목 자원에서는 일하지 않아도 괜찮다 - Firm needs sound systems, education, top-management support, and willingness to change

회사는 건전한 시스템과 교육과 최고 경양자의 지원과 변하고자 하는 의지를 필요로 한다.

7) Vendor Scheduling and Follow up

Similar to the shop-floor scheduling and control systems but

From the vendor's perspective, each customer is usually only one of many demand sources

작업장 스케줄링 및 제어 시스템과 유사하지만

공급업체의 관점에서 볼 때, 각 고객은 대개 많은 수요자 중 한 명일 뿐이다

(1) Objective of vendor scheduling

- Align orders with due dates 주문과 마감 날짜 조정

- Vendor Must have continually updated information concerning priorities (e-SCM)

공급자는 반드시 우선순위에 관한 정보를 지속적으로 갱신해야 한다 - Contractual agreements may limit the type and degree of change the vendor must accommodate

계약상의 계약으로 공급업체가 수용해야 하는 변경의 유형과 정도가 제한될 수 있음

8) The internet and vendor scheduling

- Real time information exchage and order tracking

- EDI → e-SCM, SRM

4. Control of Production

1) Scope and Principle of Operations Control

- Scope

- Manage the execution of production schedules and quality plans

생산 스케줄과 품질 계획의 실행을 관리하는 것

- Manage the execution of production schedules and quality plans

- Principle

- Fucus on production/quality results, conformance to cost/quality standards, feedback

생산/품질 결과, 원가/품질 표준 준수, 피드백

- Fucus on production/quality results, conformance to cost/quality standards, feedback

2) MRP-Based PAC

- Feedback to production control 생산 관리의 피드백

- performance of W/O's compared to planned order

planned order와 비교한 W/O의 성과 - Data on WIP, LT, queue, work center efficiency, operation times, scrap rate

- performance of W/O's compared to planned order

- Control techniques

- I/O control, priority sequencing, bottleneck management (TOC)

3) Lean-Based PAC

- Use of a pacemaker that sets the schedule for all W/C's in a line or cell

라인 또는 셀의 모든 W/C 일정을 설정하는 페이스메이커 사용

← Tackt time 유휴시간- Pacemaker 페이스 메이커

- Bottleneck, store, final assembly point, a point farther upstream

- Store (or supermarket)

- controlled inventory of parts usually in the upstream with kanbans

칸반과 함께 물류 상류에 보통 있는 부품의 재고를 관리

- controlled inventory of parts usually in the upstream with kanbans

- Pacemaker 페이스 메이커

- Others

- Heijunka, Kanban, simplified documentation of 'Hidden Factory'

4) Comparison of Push and Pull

| Characteristics | Push(MRP) | Pull(Lean) |

|---|---|---|

| Control objectives 관리 목적 | Work center capacity utilization 작업장 용량 활용율 | Overall product flow times 전반적인 상품 물류 시간 |

| Control of material flow 물류의 관리 | Push, schedules, shop orders, batches, job sequencing rules | Pull, initiated by downstream kanban card |

| Operations sequencing 운영 순서 | Important, priority at each Work center | N/A, replenish downstream stocks |

| Order tracking 주문 추적 | Important, shop-floor transactions | N/A, paperless system |

| Monitoring and feedback | Critical, I/O control, W/C load reports | N/A, focus on overall result, Kaizen |

| Preferred lot size 선호되는 lot size | Large | Small |

| WIP and Safety stock | Large | Negligible |

| product demand 제품 수요 | Low/medium vol, high variety with variable demand and L/Ts | High vol, low variety with stable demand and short LTs |

5) Inventory Management Issues

-

Point of use delivery and storage 사용 시점 제공 및 저장

- direct delivery to a work center with smaller deliveries

소규모로 작업 센터로 직접 배달 - reduced material handling cost 줄어든 자재 관리 비용

- reduced floor space requirements 줄어든 floor 공간 필요

- direct delivery to a work center with smaller deliveries

-

Item numbering principles

- use one set of unique item number→1품 1번

- Primary key : meaningful ( or intelligent) vs. nonmeaningful(or serial) codes

-

Accuracy of inventory records 재고 내역의 정확성 (Cycle Counting)

- ABC classification : some items counting every day

-

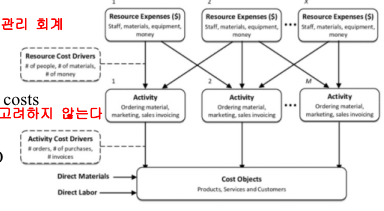

Cost control and accounting

- Full costing 전부 원가 ← 재무 회계 ; 변동 원가 ← 관리 회계

- Cost = difect + indirect (fixed + variable)

- Absorption costing 전부 원가 : full indirect costs

- Variable costing 변동 원가 : not consider fixed indirect costs 고정 간접비는 고려하지 않는다

- Cost object : product or group

- Job costing 개별 원가 : product or order → MTO/ETO

- Process costing 종합 원가 : product families 사업부 단위 → MTS

- ABC (Activity Based Costing) 활동 기준 원가

- Allocate overhead costs by activities ← absorption costing & job costing

간접비를 활동에 부과한다.

- Allocate overhead costs by activities ← absorption costing & job costing

- Total Quality Costs 총 품질 비용

- Quality conformance and costs of quality 품질 준수 및 품질 비용

6) Other Issues in ECO (Execution and Control of Operations)

(1) Management and Communication

a) Approaches to management

- Schientific management 과학적 관리

- only engineers improve processes and products

오직 엔지니어만이 프로세스와 제품을 개선한다

→ command and control- Industrial engineering 산업 공학

- measurement and analysis to improve the process 프로세스 개선을 위해 측정하고 분석한다.

- Industrial engineering 산업 공학

- only engineers improve processes and products

- Worker self-control

- the opposite of scientific management 과학적 관리법과 반대되는 것

→ Whole person concept - Workers have full knowledge of what they are supposed to do (goals)

작업자들은 그들이 무엇을 해야하는지에 대한 전체적인 지식을 가지고 있다.

- the opposite of scientific management 과학적 관리법과 반대되는 것

- Quality management leadership 품질 관리 리더쉽

- creation of a vision of total quality culture → TQM (Total Quality Mgmt)

전체 품질 문화의 비전의 생성 - Leader as change agents 변화 전도사, 개혁 청부인(6-시그마)

- lead from the front, set a clear vision for change..

- creation of a vision of total quality culture → TQM (Total Quality Mgmt)

b) Worker Development

- Workers can be held responsible for quality

작업자는 품질에 대한 책임이 있다- Quality problem are worker controllable 품질 문제는 작업자가 제어할 수 있다

- Job design principle 작업 디자인 원칙

- job enlargement and enrrich ment, self-direct teams, empowerment

직무 확대 및 강화, 자기 직속 팀, 권한 부여

- job enlargement and enrrich ment, self-direct teams, empowerment

- Performance appraisal and rewards, selection & training

성과 평가 및 보상, 선정 및 교육

c) Worker participation and involvement

- Behavior and attitudes need to change

← Changing job design and organization is not enough - Workforce teams(or quality circle; 분임조)

- team formed by volunteers from the department

- kaizen circcle : workers + managers(sponsor) + facilitator & trainer

(2) Quality and Continuous Improvement

a) 7 basic quality tools

Check sheet, histogram, pareto chart, cause/effect diagram(fishbone diagram), scatter chart, control chart, process map

b) Deming cycle or PDCA cycle in the 50's

- E. Deming developed for Japanese manufacturers including Toyota

- Plan(objectives) → Do (test or experiment) → Check (study or analysis) → Act (or adjust ; implement)

c) PDCA cycle with Grasp by Toyota ← worker self-control

- Grasp (or define) the stituation by Gemba walk (현장 우선주의)

- Critical thinking, identifying issues, find the root causes of problem

d) DMAIC procedure of 6 Sigma in the 80's

- Developed by Motorola : modifying the Deming Cycle

- Define(problem, gaol, scope) → Measure (collect data, baseline) → Analyze(root causes analysis) → Improve (test alternatives with PDCA, implement) → Control (monitor, sustainability)

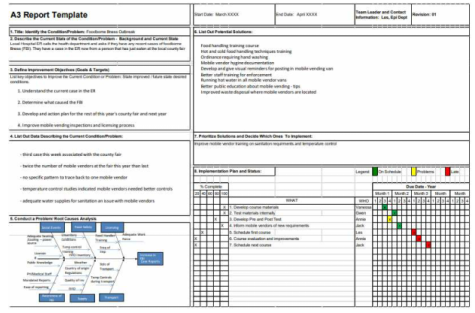

e) A3 problem solving

- Tools for the PDCA cycle

- structure and discipline ← System viewpoint and Nemawashi

구조 및 규율 ← 시스템 관점 및 Nemawashi - logical thought process, objectivity, synthesis/distillation/visualization, alignment, coherence

논리적 사고 과정, 객관성, 합성/정보화/시각화, 정렬, 일관성

- structure and discipline ← System viewpoint and Nemawashi

- A3 report format

- title, current state, objective, cause-and-effect analysis (for primary causes), countermeasures(for root causes), check(improvement↔root causes), action plan

(3) Workplace Design

a) Motion economy and ergonomics 인체 공학

- Support continuous improvement in standardized work

표준화된 업무에서 지속적인 개선을 도와준다 - Techniques : convenient & visible llocation, color coding, adequate lighting

b) Types of workplace layouts

- Islands, cconnected islands, connected islands with full work control(Kanban), cells

5. CPIM Problems

Which of the following are elements of lead time?

I. Run time

II. Setup Time

III. Queue time

a. I only

b. II only

c. I and II only

d. I,II, and III

answer : d

which of the following are sequencing rules used in pracetice?

I. First come/First Served (FCFS)

II. Earliest due date (EDD)

III. Least work remaining (LWR)

a. I only

b. I and II only

c. I and III only

d. I,II, and III

answer : d

Production activity control's (PAC) main link with the rest of the MPC system is

a. Detailed capacity planning

b. Detailed Material planning

c. Material and capacity plans

d. Master production scheduling

answer : c

Identifying bottlenecks is most often accomplished with

a. Capacity requirements planning

b. Rough-cut capacity planning

c. Value stream analysis

d. Material lrequirements planning

Theory of Constraints(TOC) systems are most concerened with

a. Reducing inventory

b. Machine efficiency

c. Bottleneck utilization

d. Labor efficiency

answer : c

Priority sequencing rules determine which of the following?

I. Allocation of goods to customer

II. Which machine(s) to serve next

III. Which job(s) to run at a work center

a. I only

b. II only

c. III only

d. I,II, and III

answer : c