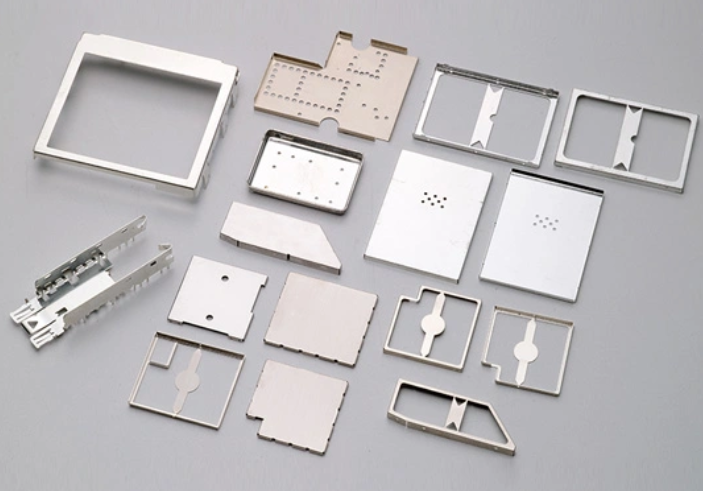

CUSTOM METAL STAMPING EMI/RFI SHIELDING

EMI shielding materials/RFI shielding parts are vital parts that protects electronic devices and equipment from electromagnetic interference and radio-frequency interference. These interferences can impact the functionality of electronic devices or can damage them completely.

Observe the below to understand EMI/RFI shielding parts performance better.

With extensive industry knowledge, innovative technology and quality materials, we manufacture emi shields/RFI shielding parts that meet different industry standards.

TYPES OF EMI/RFI SHIELDING PARTS

Electromagnetic shielding Parts

Include conductive materials like metal sheets, coatings, mesh and polymers that reflect or absorb EMI/RFI waves, preventing them from penetrating sensitive electronics and blocking electromagnetic interference.

Radiation Shielding Parts

Dense substances particularly lead, concrete, steel, and polyethylene absorb or block penetrating ionizing radiation like gamma rays, allowing the safe operation of nuclear, medical, and high-energy physics applications.

Thermal Shielding Parts

Insulating materials including foam, fiberglass, ceramics, aerogels, and vacuums that reduce or block heat flow via conduction, convection or radiation; used widely in cryogenics, spacecraft, ovens and heating/cooling conservation.

Acoustic/vibration damping Parts

Sound-absorbing, -blocking or -damping materials such as polymers, foams, constrained damping layers and vinyl barriers that decrease structural vibrations and airborne noises in machinery, engines, and architecture.

EMI/RFI Shielding Parts Materials

Choosing the right materials is essential when manufacturing EMI/RFI shielding parts because the material properties directly impact the quality of the product and reliability. Each metal stamping consumer electronics has unique requirements, only the right material will maximize performance.

Material for Shielding parts

Different kinds of materials are used in the manufacturing of EMI/RFI shielding parts according to their applications. Here are a few of them so you can understand the difference.

JCL is a leading manufacturer offering quality products to companies worldwide. We are strongly committed to our principles of trust, honesty and communication in our daily operations.

JCL sheet metal fabrication manufacturer is skilled in techniques like custom metal stamping, deep drawing and manufacturing. We manufacture custom sheet metal shieds suited to each client. Our clients believe in us for customized, affordable, high-quality solutions. As we always prioritize our client's satisfaction, this made us apart from others and made us their first choice.

WHY CHOOSE JCL FOR CUSTOM METAL STAMPING EMI/RFI SHIELDING PARTS?

JCL has years of experience efficiently custom metal stamping to manufacture quality EMI/RFI shielding parts. We manufacture customized shield parts to meet stringent functionality and precision requirements.

years of experience in EMI/RFI shielding parts

JCL’s Custom Metal Stamping Process

Our industrial metal stamping is fast, metal forming technologies are reliable, and multi-functional. We manufacture EMI/RFI shielding parts that offer exceptional performance to our clients.

Blanking - We use precision steel rule dies or hardened blanks to cleanly shear sheet metal into flat patterns that will form the foundations of EMI/RFI shielding parts. Tight tolerances were maintained on blank dimensions and edge finish.

Bending - Shielding blanks are formed into curved, angular shapes via the controlled application of localized pressure by punch and die sets. We perform versatile custom sheet metal bending like wipe, air, bottom, and coil dies to get necessary bend radii and angles.

JCL’s Custom Metal Stamping Process

Punching - Precision punch presses cut holes, slots, and specialty voids such as countersinks into stamped blanks. Let integration of fasteners, circuit access, and venting ports into EMI/RFI shielding parts. We deliver exceptional hole size/shape accuracy.

Coining - enables the formation of small radius forms in metal without distorting material or thickness using impressing between matched punch/die surfaces. Used to emboss reproducible intricate patterns onto shields.

Drawing - Complex 3D shielding cup shapes and enclosures are drawn from flat blanks via a radial stretching process using fluid cell pressure. Ideal for seamless one-piece containment shields.

Embossing - 3-dimensional surface relief patterns are pressed into the shield material using male and female roller dies to create thickness variations. Used to sculpt EMI absorption enhancement structures.

Piercing - We pierce small, clean apertures in formed EMI/RFI shielding parts using a punch and die clearance between 0.1-10% of material thickness. Lances formed Tab creating knock-out slugs are also available.

Curling – Tight-edge curls are formed to eliminate sharp EMI/RFI shielding parts edges, strengthen flanged ends and allow enhanced peripheral acoustic damping performance for airborne noise.

We also use special techniques when required for superior shielding performance, including:

Seam Joining/sheet metal welding services – Create full-enclosure Faraday cages out of stamped metal panels

Staking – Secure multiple stamped shielding layers without penetrative fasteners

JCL's agile in-house tooling and proprietary process controls enable rapid iteration of EMI/RFI shielding parts designs to meet application-specific attenuation, fit, and quality standards.

FACTORS TO CONSIDER WHEN STAMPING EMI/RFI SHIELDING PARTS

For manufacturing good quality EMI/RFI shielding parts, JCL considers a few factors throughout the production process.

Material Choice

All materials have different characteristics and functionality. For different shielding needs, you require different materials. Our expert team selects the material that aligns with your needs.

Thickness

The thicker the material, the more it blocks signals. Our experts control thickness precisely to meet shielding requirements.

Tool Design

Shielding tool design directly affects the quality of EMI/RFI shielding parts. That’s why we carefully design the stamping tools to ensure accurate and high-quality EMI/RFI shielding parts.

Testing and Improving

We do rapid testing for EMI/RFI shielding parts design. Testing and improving the design is essential for meeting their application requirements and maintaining quality.

BENEFITS OF JCL’S CUSTOM METAL STAMPING EMI/RFI SHIELDING PARTS

Precision Manufacturing

We ensure accuracy and high precision while metal stamping your EMI/RFI shielding parts. So it can meet the tight tolerance and specifications.

Customization Options

To fulfill every client's requirements, we manufacture EMI/RFI shielding parts in different sizes, colors, shapes, configurations and with different materials through our innovative metal stamping process.

Efficient Production Speed

We use new and innovative technologies for our metal stamping and manufacturing process. It makes our manufacturing process fast and effective. And our team can produce a large quantity of EMI/RFI shielding parts within a short period.

Consistent Quality

In our metal stamping, we use machines and strict controls to make the same products over and over. This makes the quality very consistent. The EMI/RFI shielding parts perform reliably because they are made the same way every time.

BUSINESS AND CUSTOMER PROCESS FLOW FOR CUSTOM METAL STAMPING SHIELDING PARTS

For ordering our EMI/RFI shielding parts, contact us online. different mediums online to discuss your requirements with our experts.

Discuss your requirements with our experts. They will closely study your requirements to plan the most effective production approach.

After finalizing all the things, our engineering team will start the metal stamping process to manufacture your products.

We will maintain strict precision and performance standards at every step.

After finishing production, we will do quality inspections. This will ensure they match all your requirements.

After that, we will package your products and ship them to your destination.

If you are looking for a reliable custom metal stamping company, please contact us.