- Overview of related project and brief introduction of manufacturing process.

- Manual_Batch_Management_System has been used for traceability of single parts before this project.

- Project description: This project is to automate current manual standardization.

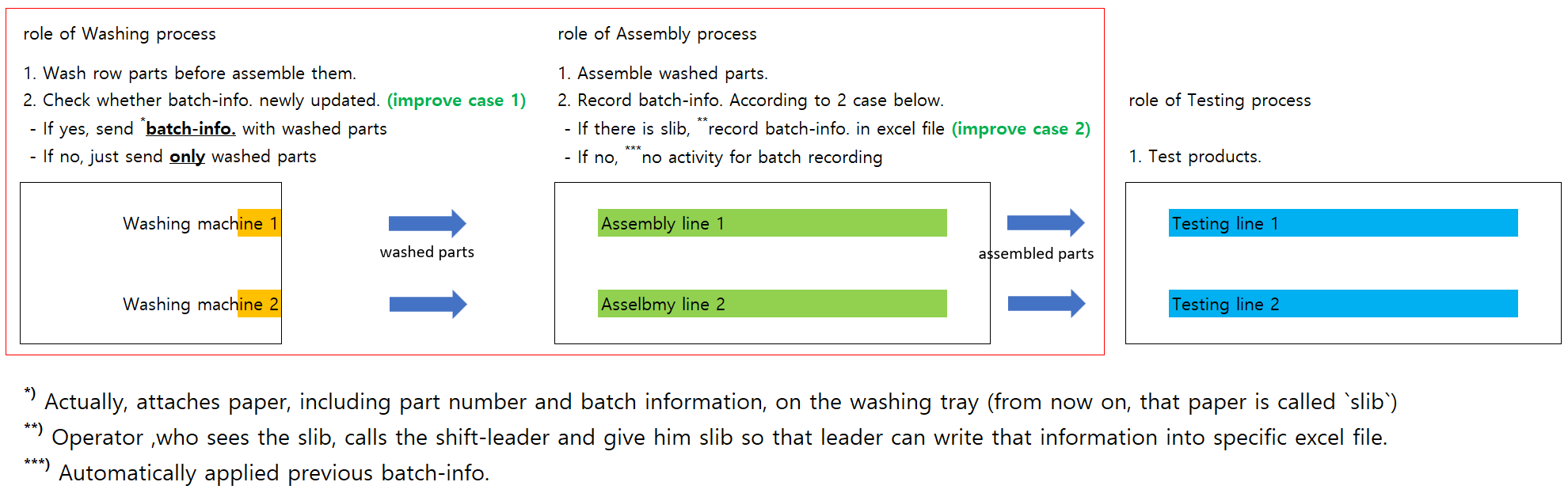

- Manufacturing process, to which related improvement are applied and current situation please see below.

- Analyzing and set direction for improving from current manual standardization.

1. Washing process: this process is quality gate of batch management system and performs the following role.

task: When parts are received with batch information, operator should determines whether delivered batch information has newly updated compared to the latest batch information written in whiteboard.

risk: Because it relies 100% on human judgement, incorrect batch information may be delivered due to mistake, or the newly updated information may not be delivered.

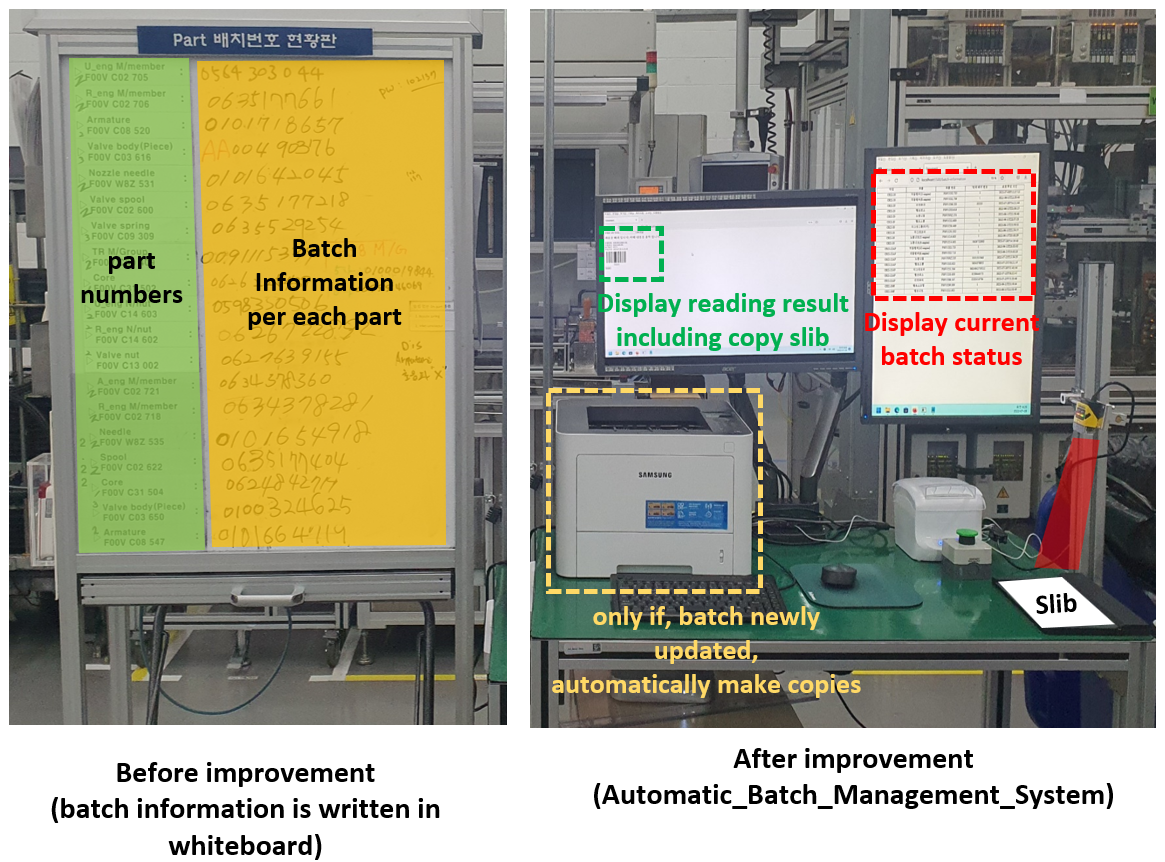

improvement: Eliminate humman error by developing system called Automatic_Batch_Management_System so that, operator can simply scan the slib and then, system check whether the batch information newly updated or not.

let me explain more about benefit after applying system as standardization.

before improvement, operator check batch information as follows.

- Operator get slib and come to whiteboard.

- Check the batch information for part number written in slib from the whiteboard.

- Compare 2 batch information from slib and what he found from whiteboard.

- If different then, erase the batch information in whiteboard and write newly updated batch information.

- make copies of slib as required numbers and send them to Assembly process with washed parts.

after improvement,

- Operator positions the slib and press the button

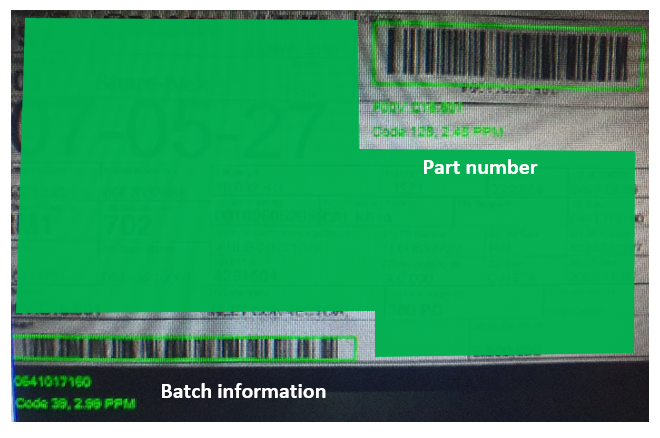

- System takes part number, batch information and check it changed or not.

- if changed, system automatically makes th copies of slib.

System takes part number and batch information from slib as shown picture above.

2. Assembly process: Actual records the newly updated batch information received from Washing process

Task 1: If there is a slib in the part tray, the operator passes the slib to the shift-leader and asks him to record it.

risk for task1: If the shift-leader is absent (meetings, personal business, etc..), real-time records are not managed and there is a risk of work being missed.

task2: Shift-leader records the new batch information into excel sheet.

risk for task2: Recording and management of changed information is dependent on the shift-leader, and data may be contaminated due to human error (record incorrect information, omission of the work and loss slib)

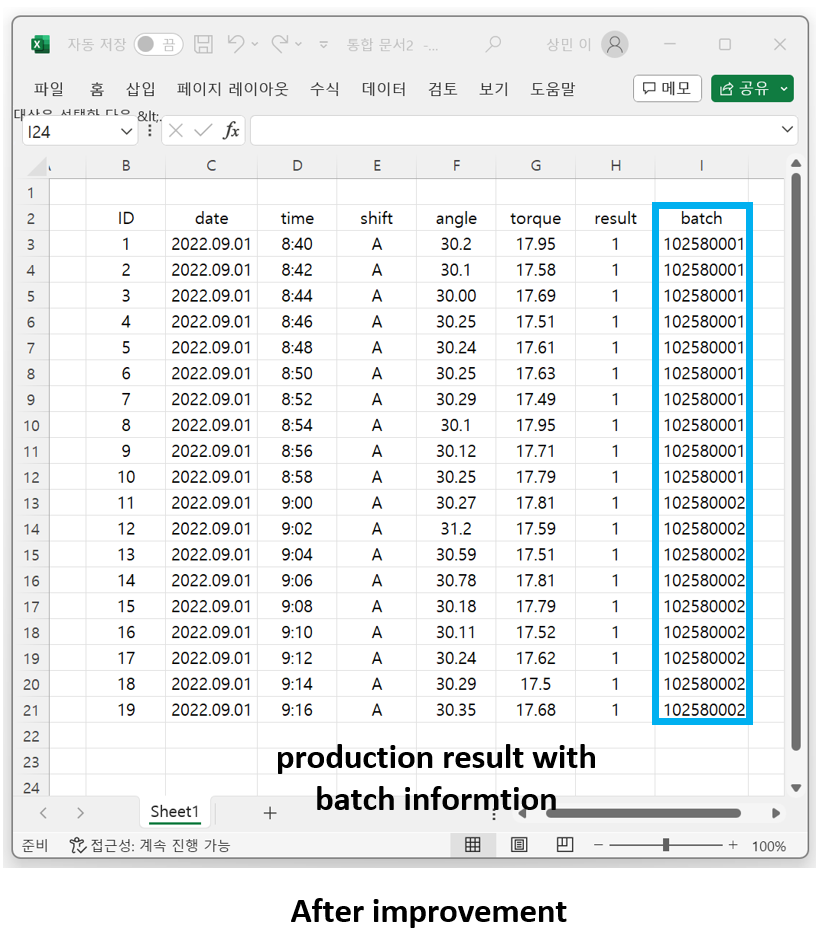

improvement: PLC was modified and a barcode reader device was provided so that operators can scan the slib immediately all by himself when they discover it. The PLC memoizes the reading information and when generates document for production result add batch information at batch column.

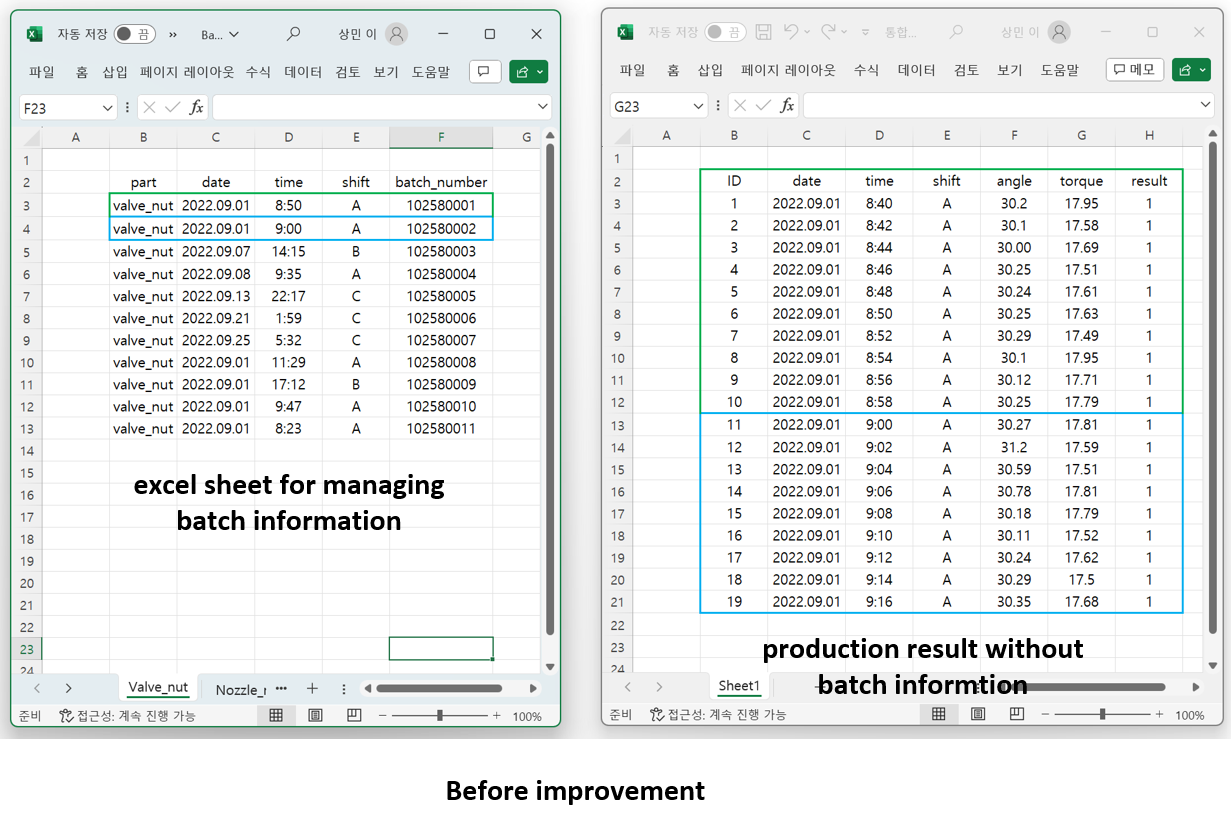

3. Engineer(Data analyst)

The reason for actually operating the above standards in the field, is to use batch information to analyze the impact of changes in raw material when something unusual occurs in the production results. However, the current standard has two drawback.

First drawback is, batch information and production result they are decoupled, so there might be necessary for additional merging work.

Second drawback is during additional work to merge 2 different data set, engineer can also make mistake.

As shown below picture, production result and batch information they are decoupled.

After improvement, there is column batch in production result sheet.

- Outcome and role I took.

Benefit after applying Automatic_Batch_Management_System

- Guarantee 100% good quality by achieve 0% humman error,

- Accuracy and productivity increased for data analysing work.

- Decrease manual work loss

In carrying out above project, I played leading role as project leader for below tasks.

- Schedule management.

- Analysis of problems and derivation of improvement direction,

- Personally developed, distributed the

Automatic_Batch_Management_Systemincluding training user

(Regarding improvement of PLC was supported by PLC engineer from maintenance Dept.) - Update standardization

For source code for Automatic_Batch_Management_System you can refer with link belw.

Click me for source code for this project.