Liquid Silicone Rubber Market: Balancing Performance and Sustainability

Liquid silicone rubber (LSR) is increasingly being recognized as a material of choice in high-demand industries due to its superior mechanical, thermal, and chemical properties. With excellent biocompatibility, stability at extreme temperatures, and resistance to wear and tear, LSR is widely used in applications that require long-term reliability. From medical implants to automotive components and smart electronics, the liquid silicone rubber market is growing steadily as manufacturers seek advanced solutions to meet evolving customer and regulatory demands.

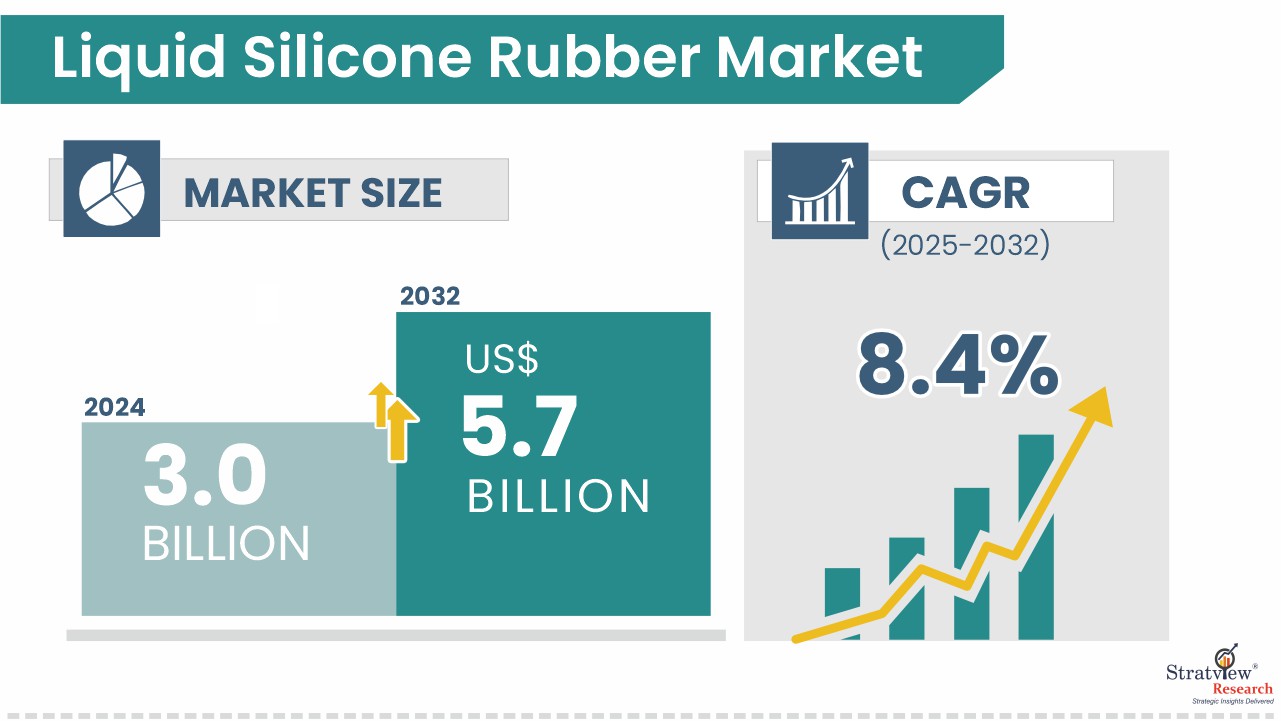

According to Stratview Research, the liquid silicone rubber market was estimated at USD 3.0 billion in 2024 and is likely to grow at a CAGR of 8.4% during 2025-2032 to reach USD 5.7 billion in 2032.

Request Sample Page Now:

https://www.stratviewresearch.com/Request-Sample/792/liquid-silicone-rubber-market.html#form

Market Drivers

The medical device industry remains one of the largest consumers of LSR. Its non-toxic, non-reactive, and sterilizable characteristics make it indispensable for surgical tools, implants, and diagnostic equipment. The rising prevalence of chronic diseases and the expansion of healthcare access in emerging economies are driving significant growth in this sector.

The automotive sector is also fueling demand. With electrification and lightweighting trends, automakers are increasingly turning to LSR for components that provide durability, high resistance to heat, and precision molding for complex designs. The adoption of EVs, in particular, is creating new opportunities for LSR in battery seals, charging connectors, and thermal management systems.

In consumer electronics, miniaturization and enhanced device durability are creating demand for LSR in sealing, insulation, and protective applications. Its resistance to UV and environmental degradation makes it ideal for devices that must endure challenging conditions.

Technological innovations such as LSR-based 3D printing are further shaping the market. These advancements allow for greater design flexibility, shorter lead times, and efficient customization, opening doors for new applications in prototyping and small-batch production.

Challenges

The market is not without hurdles. High production and tooling costs limit widespread adoption, especially in markets with thin margins. Smaller manufacturers often struggle to justify the upfront investment in equipment and molds required for LSR processing.

Competition from thermoplastic elastomers (TPEs) is another challenge. While LSR offers superior properties, TPEs are more cost-effective and easier to process in some applications, making them a preferred choice in certain industries.

Additionally, environmental sustainability remains a concern. Recycling and disposal of silicone materials pose difficulties, prompting calls for innovation in eco-friendly solutions and circular material use.

Conclusion

The liquid silicone rubber market is expanding rapidly as industries seek reliable, high-performance materials. Its unmatched durability, flexibility, and biocompatibility make it a preferred choice in critical applications across healthcare, automotive, and electronics. Although cost pressures and sustainability challenges remain, continuous advancements in processing and material innovation will ensure LSR’s position as a key enabler of modern product design and manufacturing.