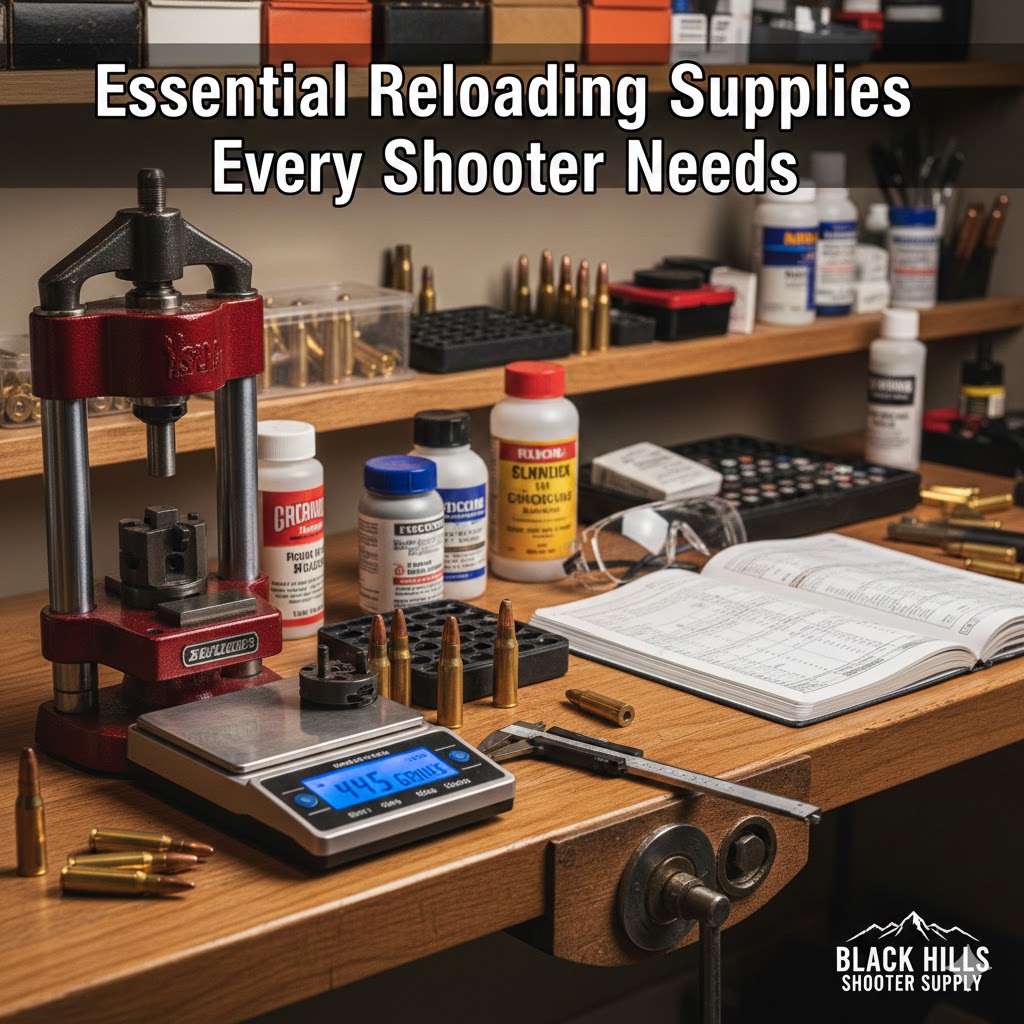

Essential Reloading Supplies Every Shooter Needs

Reloading ammunition at home gives shooters control over precision, performance, and cost savings that factory rounds simply can't match. Whether you're a competitive shooter refining your accuracy or a hunting enthusiast preparing for the next season, having the right supplies transforms your shooting experience. Explore quality products at black hills shooter supply to get started on your reloading journey today.

Why Quality Reloading Gear Matters for Shooters

Investing in reliable reloading equipment directly impacts the consistency and safety of your ammunition. Low-quality tools can produce inconsistent powder charges, improperly seated primers, or case deformities that affect accuracy and create dangerous pressure issues. When you're handloading rounds, every component plays a role in how your ammunition performs downrange.

Quality gear also lasts longer and requires less frequent replacement. A well-made reloading press, for instance, maintains its alignment and tolerances through thousands of rounds, while cheaper alternatives may develop play or misalignment after minimal use. This durability translates to better long-term value despite higher upfront costs.

Experienced reloaders understand that precision equipment produces ammunition that outperforms factory loads. You'll notice tighter groups at the range, more predictable ballistics, and the ability to tailor loads to your specific firearm. The difference between budget and premium reloading supplies becomes evident with every trigger pull.

Core Components for Reliable Ammunition

Primers serve as the ignition source for your ammunition and come in several varieties including small rifle, large rifle, small pistol, and large pistol types. Each cartridge requires a specific primer size and strength, with magnum primers used for larger powder charges or slower-burning powders. Always match primer specifications to your load data exactly, as using the wrong type can create dangerous pressure spikes or misfires.

Gunpowder selection determines your ammunition's velocity, pressure curve, and overall performance characteristics. Powders range from fast-burning varieties suitable for pistol cartridges to slow-burning types designed for magnum rifle rounds. Never substitute one powder for another without consulting reliable load data, and always measure charges with precision scales to maintain consistency and safety.

Bullets and brass casings complete your ammunition's core components. Brass cases can be reused multiple times if properly inspected and sized, making them cost-effective for high-volume shooters. Bullet selection depends on your intended use, with options including full metal jacket for practice, hollow points for defense, and specialized hunting projectiles. Quality brass and bullets from trusted manufacturers ensure reliable feeding and consistent performance across all your loads.

Must-Have Tools and Equipment

A sturdy reloading press forms the foundation of your setup and comes in single-stage, turret, or progressive configurations. Single-stage presses work best for beginners and precision rifle loaders who prioritize accuracy over speed. These presses perform one operation at a time, allowing careful attention to each step. Turret and progressive presses increase production rates for shooters who need higher volume output while maintaining acceptable quality standards.

Precision scales and powder measures ensure you're charging cases with exact powder weights. Digital scales offer convenience and quick readings, while beam scales provide reliability without batteries or electronics. A quality powder measure with adjustable settings speeds up the charging process, though many reloaders still weigh each charge individually for maximum consistency in precision loads.

Case preparation tools including resizing dies, case trimmers, and chamfer tools prepare your brass for reloading. Dies resize fired cases back to proper dimensions, seat bullets to correct depths, and crimp case mouths when needed. A case trimmer maintains uniform case length, which affects pressure and accuracy. Calipers let you measure case lengths, overall cartridge dimensions, and bullet seating depths with precision. These measuring tools prevent dangerous over-length cases and ensure your ammunition functions reliably in your firearms.

The Beginner's Reloading Checklist

Press and Dies

-

Single-stage reloading press

-

Die set for your caliber (resize, seat, crimp)

Measuring Tools

-

Digital or beam scale

-

Calipers for case and cartridge measurements

Components

-

Brass cases (new or once-fired)

-

Primers (correct size for your cartridge)

-

Gunpowder (matched to your load data)

-

Bullets (appropriate weight and type)

Preparation Tools

-

Case trimmer and deburring tool

-

Primer pocket cleaner

-

Case lube for resizing

Safety Items

-

Safety glasses

-

Current reloading manual

-

Loading block or tray

Storage

-

Ammo boxes for finished rounds

-

Containers for component organization

Safety Practices and Storage Tips

Proper powder and primer storage prevents accidents and maintains component freshness. Store these materials in cool, dry locations away from heat sources, sparks, or open flames. Original containers provide the best protection and keep critical load data accessible. Never store large quantities of primers together, and keep powders in their labeled containers to avoid dangerous mix-ups that could result in catastrophic overcharges.

Your reloading workspace should be organized, well-lit, and free from distractions. A dedicated reloading bench with storage for components keeps everything within reach while maintaining order. Label all containers clearly and keep a detailed log of your loads including powder type, charge weight, primer brand, and bullet specifications. This documentation helps you replicate successful loads and troubleshoot any issues that arise.

Always wear safety glasses when reloading and follow published load data from reputable sources. Start with minimum charges and work up gradually while watching for pressure signs. Never exceed maximum loads listed in manuals, even if online sources suggest higher charges are safe. Double-check each powder charge before seating bullets, and inspect every completed round for defects. One moment of carelessness can create dangerous ammunition, so develop consistent safety habits that become second nature at your bench.

Final Thoughts on Building Your Reloading Setup

Building a complete reloading setup requires careful planning and gradual investment in quality components. Start with essential items like a reliable press, a proven die set for your caliber, and accurate measuring tools before adding convenience items. As your skills develop, you'll identify which upgrades provide the most value for your specific needs and shooting disciplines.

Finding reliable suppliers makes the difference between frustration and success in this hobby. Browse the full selection at black hills shooters supply to find primers, powders, bullets, and brass from manufacturers known for consistency and quality. Established suppliers stock hard-to-find components and provide the selection needed to experiment with different load combinations.

The reloading community offers tremendous support through forums, clubs, and experienced mentors who share knowledge freely. Don't hesitate to ask questions and learn from those who've spent years perfecting their craft. With proper equipment, attention to detail, and commitment to safety, you'll produce ammunition that performs better than factory loads while enjoying the satisfaction of crafting custom rounds tailored to your exact specifications. Your investment in quality reloading supplies pays dividends with every accurate shot and every dollar saved on ammunition costs.