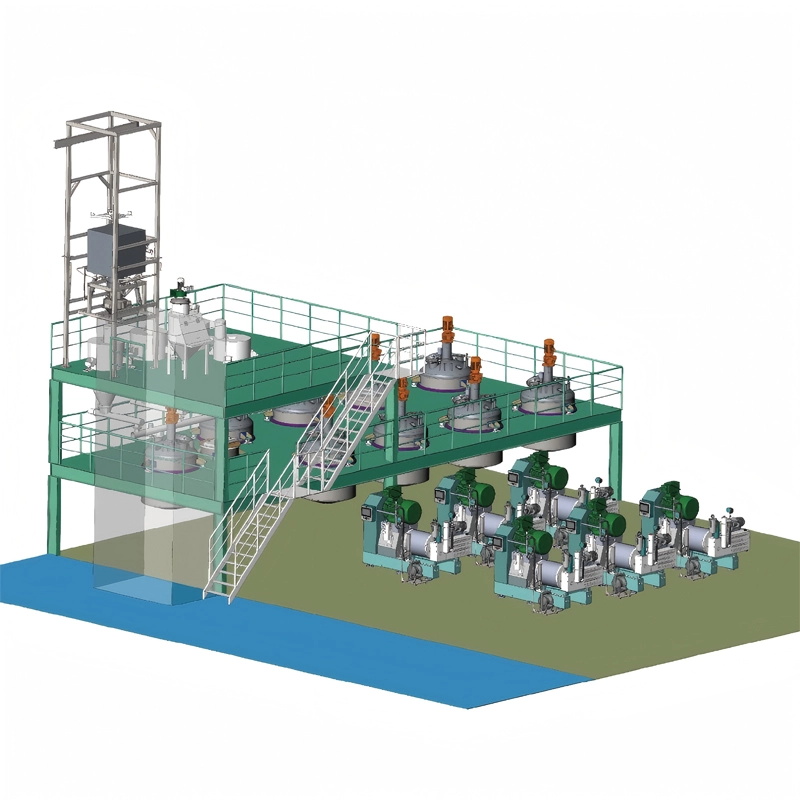

Battery Anode Material Automatic Production Line

The anode material are dropped by gravity from the ton bag feeding station/dust-free feeding station and put into the metering bin through the iron remover. After precise weight loss measurement, the materials are fed into the premixing tank. After full stirring, the material enters the bead mill. After coarse grinding and dispersion, fine grinding and dispersion are carried out before demagnetization.

Advantages of anode batteries Material Automatic Production Line

◎ Small footprint, high-level automation, and intelligent digital factory management

Main Process of Chemical Processing Equipment in Battery Anode Material Automatic Production Line

Powder batching → Solvent batching → Mixing and dispersing → Iron removal → Grinding and dispersing → Mixing → Transfer storage → Coating

Main Equipment Used in Battery Anode Material Automatic Production Line

➀ Ton bag feeding station

➁ Dust-free feeding station

➂ Measuring tank

➃ Premix tank

➄ Bead mill

➅ Storage tank

For more information about graphite lithium battery and carbon nanotube, please feel free to contact us!

There are many grinding equipment suppliers, but we are one of the best choices for you.