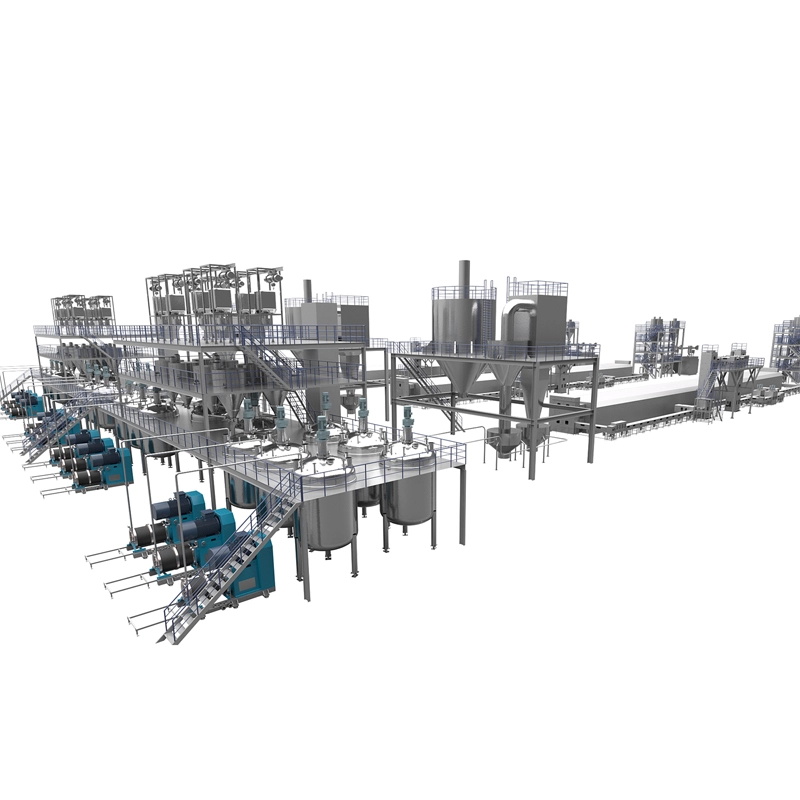

Battery Cathode Material Automatic Production Line

Battery cathode material automated production line. The entire production line include feeding and batching system, nano-grinding system, spray drying system, kiln sintering system, airflow crushing system, a screening and packaging system, a slurry pipeline transportation system, a powder pipeline transportation system, and automated control.

Advantages of Battery cathode material Automatic Production Line

◎ Rich experience in design, construction, and operation application during the implementation of other projects in the same industry ensures that the production line has high reliability, advancement, economy, and scalability.

◎ Designed with the industrial control 4.0 standard, central control management, automatically fed back signals, production line and workshop monitoring, automatic diagnosis, early warning and alarm functions, multi-level authority management of parameters, data recording and analysis, strong error prevention capabilities, and a high degree of automation.

◎ Currently, there are three production bases in Dongguan, Guangzhou and Hubei, with more than 1,000 employees. The core components are processed and produced independently, which can ensure that the high-quality production line is delivered to the owner on schedule.

For more information about LCO batteries, please feel free to contact us!

There are many equipment manufacturers, but we are one of the best choices for you.